Aluminum alloy 6063-T5 has become pretty popular in various industries because it strikes a good balance between strength and weight while resisting corrosion over time. According to ASM International's 2022 report, this alloy can handle tension forces up around 27 ksi before breaking, with a yield strength sitting at approximately 21 ksi. What makes it stand out is how light it actually is for such strong properties, weighing just 2.7 grams per cubic centimeter. Another thing worth mentioning is its ability to maintain shape and size even when exposed to extreme temperatures ranging from as cold as minus 20 degrees Celsius all the way up to 150 degrees Celsius. Because of these characteristics, many manufacturers find it especially suitable for things like outdoor equipment installations where weather conditions vary greatly throughout the year, as well as protective covers for machinery that need consistent structural integrity despite environmental changes.

6063-T5’s metallurgical structure enables efficient load distribution across its cross-section. Testing shows:

| Property | 6063-T5 | 6061-T6 | Advantage |

|---|---|---|---|

| Tensile Strength (ksi) | 27 | 45 | Better formability |

| Thermal Conductivity | 218 | 167 | Improved heat dissipation |

| Corrosion Resistance | 5/5 | 4/5 | Superior in harsh environments |

For architectural and industrial uses, the alloy's anodized surface provides 300% better corrosion resistance than untreated aluminum (ASM Metals Handbook). Its mechanical properties support modular framing systems while maintaining <25 µm surface roughness for precision fits.

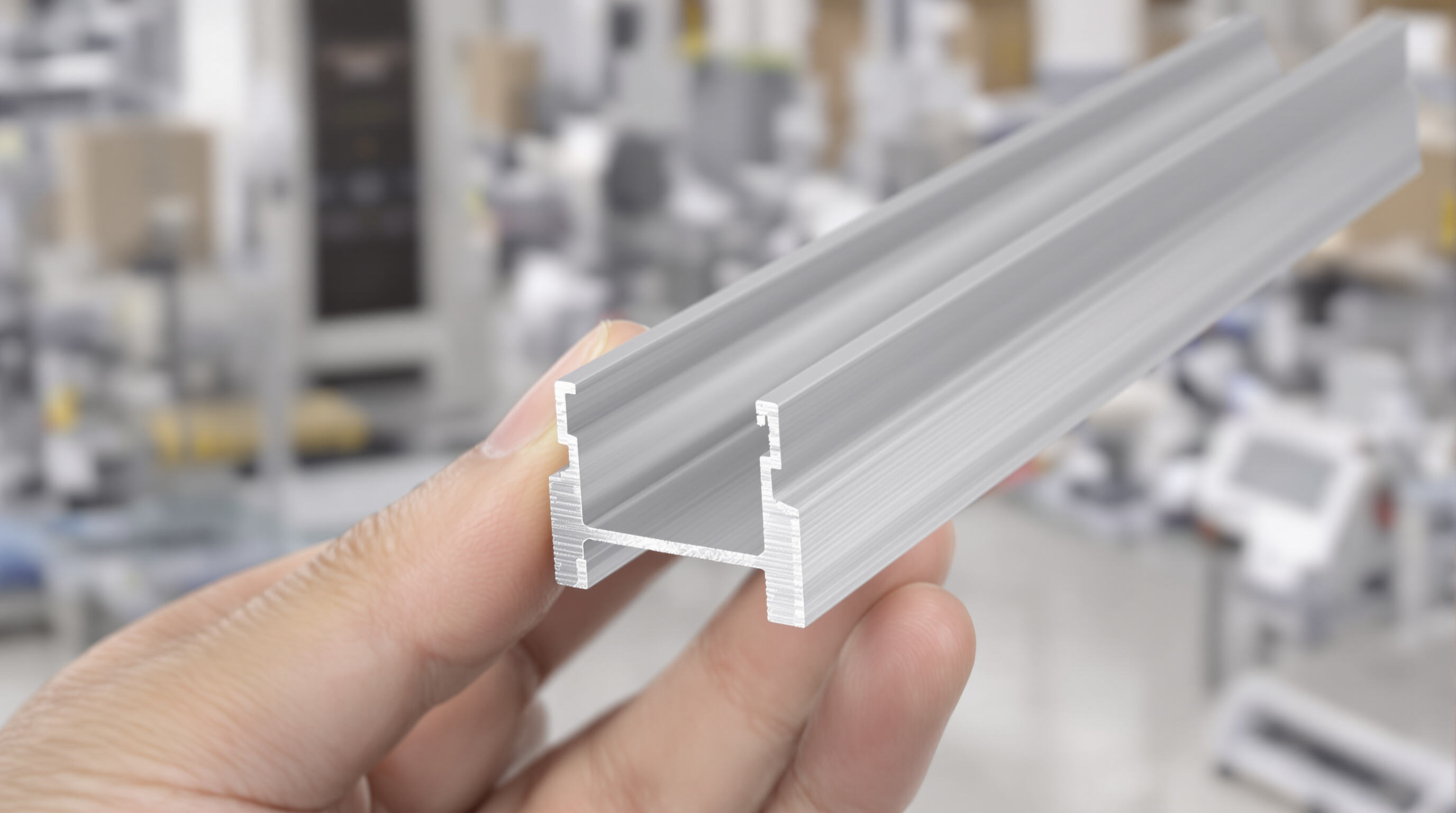

The material’s extrudability allows complex profiles like the 30mm à 30mm T-slot with 8mm grooves—reducing assembly time by 40% compared to welded alternatives. These characteristics make 6063-T5 the preferred choice when balancing structural performance with manufacturing efficiency.

The 3030 aluminum profile stands out for its impressive structural strength thanks to that standard 30 by 30 mm cross section and the special 6063-T5 alloy mix. According to recent material property studies from 2023, this alloy has a yield strength around 215 MPa which means it can handle pretty heavy bending forces before showing any signs of deformation. When designing with these profiles, engineers pay close attention to those T slot measurements – typically either 8mm or sometimes 8.2mm wide – along with varying wall thicknesses between about 1.5mm and 2.2mm. These small adjustments make all the difference in how evenly weight gets distributed throughout industrial frames and structures.

While the 2020 profile (20mm à 20mm) supports light loads up to 120 kg in static applications, the 3030 doubles this capacity for medium-duty use. Larger 4040 extrusions (40mm à 40mm) outperform both for heavy machinery but add 35% more weight. This table highlights key differences:

| Profile | Max Static Load (kg) | Weight per Meter (kg) | Common Applications |

|---|---|---|---|

| 2020 | 120 | 0.8 | Display stands, small enclosures |

| 3030 | 250 | 1.2 | Workstations, conveyor systems |

| 4040 | 400 | 1.6 | Robotic arms, heavy-duty shelving |

The 3030’s T-slots enable tool-free assembly while maintaining structural stability. Precision-machined slots (8.2mm ±0.1mm tolerance) allow accessories like brackets and panels to lock securely, reducing lateral movement by 42% compared to welded joints (Industrial Framing Systems Study 2022). This modularity supports quick reconfiguration without compromising frame stiffness.

At 1.2 kg per linear meter, the 3030 aluminum extrusion weighs 60% less than equivalent steel frames while maintaining 85% of its compressive strength. This balance makes it ideal for automation equipment where weight reduction lowers energy costs but structural reliability remains critical.

The 3030 aluminum profile redefines adaptable engineering through its modular architecture and customizable design parameters. Its standardized 30mm x 30mm cross-section serves as a universal building block, enabling rapid prototyping and structural modifications without compromising load-bearing capacity.

The T-slot configuration allows tool-free assembly, empowering users to construct, disassemble, and reconfigure frameworks in minutes. This flexibility proves critical in industrial settings where machinery layouts frequently evolve, reducing downtime during production line adjustments by up to 40% compared to welded alternatives.

Three key adaptation methods unlock specialized solutions:

These capabilities enable deployment in unconventional scenarios like cleanroom instrumentation racks and seismic testing platforms.

The profile’s 8.2mm slots maintain backward compatibility with legacy 8mm connectors while offering enhanced stability for modern accessories:

| Accessory Type | Primary Benefit | Common Use Case |

|---|---|---|

| Sliding Nuts | Positional adjustability | Sensor mounting |

| Hinged Brackets | Angular customization | Access panel installations |

| Threaded End Caps | Load distribution optimization | Structural termination points |

This interoperability ensures seamless integration across generations of industrial equipment and automation systems.

The 3030 aluminum profile system provides strong structural support for industrial equipment housing and various safety applications. These profiles feature T-slot designs that make it much faster to assemble machinery housings. The housings then protect delicate parts from dirt, dust, and other environmental hazards while still allowing proper airflow. For safety enclosures, manufacturers rely on how rigid these profiles are to build machine guards that meet OSHA standards. These guards can handle pretty serious impacts that happen regularly on factory floors. Plus, since they resist corrosion so well, these systems last longer in tough environments where chemicals are present. Think about places like electroplating shops or meatpacking plants where regular maintenance would normally be required more often than not.

Many factories turn to 3030 extrusion framing for building workstations that can stand up to the wear and tear of everyday shop floor activity. These aluminum profiles handle quite a bit of weight too around 250kg per meter if they're correctly supported, which means they can hold those big jigs and fixtures without bending out of shape after hundreds of assembly cycles. What makes them really handy are those built-in T-slots along the frame. Workers can just snap on storage bins, install task lights, or mount monitors right onto the framework without having to cut holes or weld anything extra on. The whole setup creates flexible work areas that stay dimensionally stable throughout long production runs, cutting down on assembly line stoppages when adjustments need to be made between shifts.

Precision automation relies on the 3030 aluminum profile for constructing motion carriage systems requiring micron-level accuracy. Its thermal stability (±0.1mm distortion per °C temperature change) maintains alignment for linear guide rails during high-acceleration movements. Key operational specifications include:

| Application Purpose | Profile Performance | Impact on Automation |

|---|---|---|

| Conveyor Framing | Vibration damping at <5µm amplitude | Prevents product misalignment |

| Sensor Mounting | Non-magnetic properties | Eliminates measurement interference |

| Actuator Support | Natural frequency resistance >80Hz | Reduces harmonic resonance |

More and more industrial cobot setups are turning to 3030 profiles for their base frames because these offer solid rigidity without making things heavier. Made from aluminum alloy, they stay put even when moving across multiple axes, bending less than 0.15mm per meter under full load stress. Such accuracy makes all the difference for delicate work like putting together tiny components or aligning lasers precisely, where any wobble can ruin the whole batch. What's also neat is how these profiles come with built-in cable management via those T-slots along the sides. This means power and data lines run inside the frame itself rather than hanging around outside, so there's no chance of wires getting tangled up mid operation during those complicated robotic movements.

The 3030 aluminum profile is now pretty much everywhere in makerspaces and DIY circles because of how easy it is to assemble. People love working with those T-slots for building robot frames, making custom shelves, or putting together workshop tools without needing to weld anything or buy expensive gear. Made from 6063-T5 alloy, this stuff stays strong but isn't too heavy, so folks can keep tweaking their designs over and over again. Think about someone trying out an automatic watering system for plants or figuring out the best enclosure for their 3D printer. A recent survey found that around 7 out of 10 makerspace managers consider these aluminum extrusions essential when groups need to quickly change things around during collaborative projects.

More designers are turning to 3030 aluminum profiles these days for making that cool industrial look furniture which somehow manages to be both strong enough to last forever and still looks super clean and modern at the same time. The standard size of 30 by 30 millimeters works great for those cantilever shelves that can hold around 220 pounds if they're properly supported with brackets. Plus, the anodized coating helps prevent rust even in places where there's lots of moisture, so it's actually pretty good for bathroom storage solutions or outdoor patio furniture setups. We've seen this material show up everywhere lately in modular living arrangements too. People love building wall mounted desks and those adjustable room dividers that fit into small city apartments. Crafty folks often mix these aluminum frames with bamboo panels or tempered glass to build workstations that double as something else entirely when not being used for serious projects. Some even transform them into full on workshop tables right in their home office space.

The tensile strength of 6063-T5 aluminum alloy is around 27 ksi according to ASM International's 2022 report.

The T-slot design enables tool-free assembly, making it easier to construct and reconfigure frameworks, and enhances structural stability by reducing lateral movement.

Yes, 3030 aluminum profiles are suitable for outdoor use due to their corrosion resistance and ability to maintain dimensional stability in various environmental conditions.

Common applications include workstations, conveyor systems, machine guards, automation systems, and DIY projects like furniture and shelving.