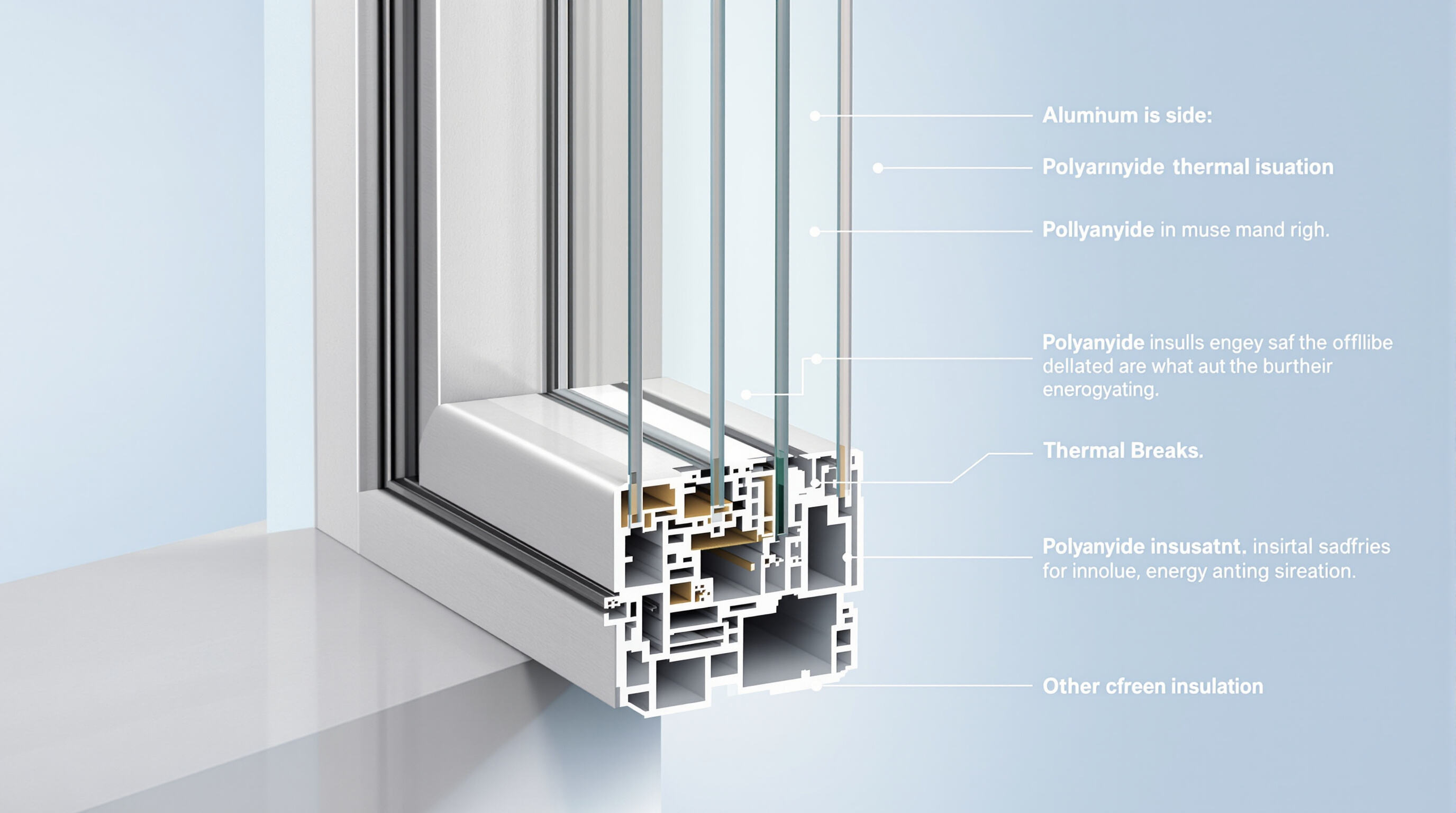

Modern windows often rely on aluminum profiles as their backbone, basically putting together extruded aluminum parts with glass and various hardware components. What makes these profiles stand out is how they manage to be both tough and light at the same time. Tests show they're roughly 35 percent stronger than vinyl alternatives which matters a lot when dealing with harsh weather conditions. The best ones are manufactured with incredible precision, sometimes within just 0.1 millimeter tolerance, allowing them to fit perfectly into buildings without causing problems down the road. Plus, they don't warp or rust over time. Inside those aluminum frames there are hollow spaces that cut down on overall weight by around 40%. These empty areas also serve another purpose: they create space for thermal breaks which help keep buildings warmer in winter and cooler during summer months.

Most window systems use 6xxx-series aluminum alloys, with 6063-T5 and 6061-T6 as industry standards. These alloys offer distinct advantages depending on application:

| Property | 6063-T5 | 6061-T6 |

|---|---|---|

| Tensile Strength | 27,000 psi | 42,000 psi |

| Thermal Conductivity | 218 W/m-K | 180 W/m-K |

| Typical Applications | Residential | Commercial |

6063-T5 dominates residential use due to its excellent extrudability and surface finish, while 6061-T6’s superior strength suits large commercial windows. Recent advancements in 6005-T6 alloys show 15% better fatigue resistance, making them ideal for high-rise applications (2023 Aluminum Association Report).

Modern aluminum profiles ensure structural stability through three core design principles:

Optimized designs reduce air infiltration by 73% compared to basic profiles, according to a 2024 Architectural Testing Laboratory study–demonstrating how geometry enhances both energy efficiency and structural resilience.

Thermal breaks work by inserting non-conductive materials such as polyamide between the inside and outside parts of aluminum window frames. This helps stop what's called thermal bridging where heat moves straight through the metal. The difference is pretty significant too - studies show around half less heat transfer when compared with regular frames that don't have this break. When we isolate those conductive metals from transferring heat so easily, several good things happen at once. Less energy escapes from buildings, rooms stay warmer during winter months, and heating bills actually go down over time. For anyone interested in building efficiency, thermally broken aluminum windows can reach U-values around 0.8 W/m2K which makes them about 40 percent more efficient than standard aluminum according to research published by Passive House Institute back in 2023.

Standard aluminum frames don't have proper thermal insulation, which means they let in more moisture and lose heat quickly when temperatures drop outside. Warm edge systems that include those special polyamide spacers actually maintain indoor surface temperatures around 15 to 20 degrees Fahrenheit higher during winter months, cutting down on condensation problems substantially. Sure, going with regular aluminum saves money initially since it costs about 20 to 30 percent less at purchase time. But over time, homeowners who install warm edge windows typically see their annual heating bills go down by somewhere between $180 and $240 per window according to recent ENERGY STAR findings from last year.

U-values measure heat transfer, with lower numbers indicating better insulation. Modern aluminum profiles achieve U-values between 0.8–1.2 W/m²K through key features:

| Feature | Impact on U-Value |

|---|---|

| Thermal break width | 24mm breaks improve U-value by 35% vs. 12mm |

| Insulated glazing | Triple glazing reduces U-value by 0.3–0.5 |

| Frame cavity fillers | Aerogel insulation cuts heat loss by 22% |

The glazing and sealing parts of a window actually make up around 60 to 70 percent of its overall U-factor rating. Those Low-E coatings on the glass do something pretty cool they bounce back about 90 percent of all that infrared heat trying to escape. Meanwhile, triple glazed windows filled with argon gas work alongside those silicone compression seals to keep air leakage really low, somewhere below 0.3 CFM per foot. Throw in some thermally broken aluminum frames for good measure, and suddenly we're talking about whole window performance numbers that hit Passive House requirements at or under 0.14 BTU per hour square foot degree Fahrenheit. Pretty impressive stuff when looking at building efficiency standards today.

Aluminum profiles stand up really well structurally because they naturally resist corrosion. Most aluminum alloys form a protective oxide layer when exposed to air, which guards against things like moisture, salt from the ocean air, and damage from sunlight. This makes these materials work great in places near the coast or inside factories where conditions can be tough on regular materials. According to research published last year by the AMPP organization, aluminum frames only showed about 2% wear and tear after sitting outside for fifteen years in areas with lots of humidity. That's actually better than what happens to steel structures or wood that hasn't been treated properly. The long lasting nature of aluminum means companies save money too since they don't have to repaint or maintain these materials as often as other options would require.

Aluminum windows built today typically stand the test of time, often lasting well over four decades if installed correctly. According to testing done by the National Association of Home Builders in 2022, these metal frames hold about 92 percent of their strength even after enduring thousands of hours模拟雨淋、冻融循环和热冲击测试. That's pretty impressive compared to other materials. Vinyl tends to buckle when temps hit around 140 degrees Fahrenheit, while wood naturally succumbs to rot over time. Aluminum just keeps its shape no matter what Mother Nature throws at it, working reliably whether it's freezing cold at minus 40 or sweltering hot up to 180 degrees.

Most aluminum window frames can be recycled around 95% without losing their quality, which keeps roughly 8.2 million tons out of landfills each year according to Aluminum Association data from 2023. When it comes to making new products from scrap aluminum instead of raw materials, the energy saved is staggering—about 95% less needed compared to producing virgin aluminum. This translates into a carbon footprint that's about 80% smaller than what we see with PVC options on the market today. Many top manufacturers have started including around 70% post consumer recycled material in their products these days. This approach fits right into the circular economy model that environmental groups keep emphasizing in their latest sustainability reports worldwide.

When it comes to building materials, engineers really get excited about aluminum because of its impressive strength-to-weight ratio, around 26 kN·m per kg. They achieve this by using those multi chamber profiles along with reinforced corners in their designs. According to tests run by ASTM International, these aluminum frames can actually hold up against wind speeds reaching 145 miles per hour, which makes them roughly 35 percent tougher compared to regular single pane vinyl options out there on the market. What does all this mean practically? Well, architects can create much thinner window frames, sometimes as slim as just 1.8 inches wide, without compromising safety standards. Plus, they still meet those important ISO 18064 seismic requirements needed for constructing tall buildings safely.

Aluminum profiles enable clean, minimalist sightlines with face widths as narrow as 45mm (European Aluminium 2023). Their structural efficiency maximizes glass area, enhancing natural light and unobstructed views–key benefits for contemporary residential and commercial designs focused on openness and visual continuity.

Advanced anodizing and powder-coating technologies offer over 200 RAL color options, including woodgrain textures and metallic finishes. These coatings bond molecularly with aluminum, providing fade resistance for 20+ years–even in harsh coastal conditions. Profiles can also be curved or angled to match complex architectural forms, offering unmatched design adaptability.

Aluminum window frames work really well across all sorts of building designs, whether it's those big glass walls in steel skyscrapers or the inset windows typical of concrete brutalist buildings. What makes these profiles stand out is how they pair nicely with energy saving glass options and can be connected to smart home tech too. Most architects seem to agree on this point actually - around two thirds of them choose aluminum when working on modern style buildings that need good performance along with looking sharp aesthetically speaking.

Aluminum windows generally come with a price tag that's about 20 to 40 percent higher than vinyl options at first glance. However, these windows last well over four decades and save money on energy bills, making them worth the investment in the long run. When we look at thermally broken aluminum systems specifically, they cut down on yearly heating and cooling expenses somewhere between 30% and maybe even half (according to Windowrama from last year). Most people find that their initial outlay pays itself back within around seven to twelve years. And interestingly enough, many homeowners end up getting back roughly 85% to over 100% of what they spent installing these windows thanks to those ongoing energy savings plus boosted home values as reported by Remodeling Magazine recently.

Top manufacturers differentiate themselves through:

Price differences of up to 35% exist between brands for similar specifications, underscoring the importance of technical evaluation over brand reputation alone.

Modern aluminum systems deliver lifecycle value through strategic material choices:

| Factor | Cost Impact | Value Benefit |

|---|---|---|

| Recycled content | +8-12% | 95% recyclability rate |

| Thermal break design | +15-20% | 30-year condensation warranty |

| Powder coating | +5-10% | 25-year fade resistance |

This balance of upfront investment and long-term performance explains why 68% of architects now select aluminum profiles for projects demanding aesthetic flexibility and lifecycle cost efficiency (NAHB 2024).

Aluminum window profiles are strong, lightweight, and resistant to corrosion. They do not warp or rust, making them durable. Additionally, their thermal breaks improve energy efficiency, and they offer aesthetic flexibility for modern designs.

Thermal break technology involves inserting non-conductive materials, like polyamide, between the aluminum frames to minimize heat transfer, enhancing energy efficiency and reducing heating bills.

Though initially more expensive, aluminum windows offer long-term savings on energy bills, last over four decades, and increase home value, making them a worthwhile investment.

Yes, aluminum frames are highly recyclable, with a recyclability rate of around 95%, which significantly reduces environmental impact.