Aluminium extrusion profiles are manufactured through a thermomechanical process that transforms cylindrical aluminum billets into precisely shaped cross-sections. This method balances efficiency with material integrity, making it ideal for creating components used in construction, automotive, and aerospace industries.

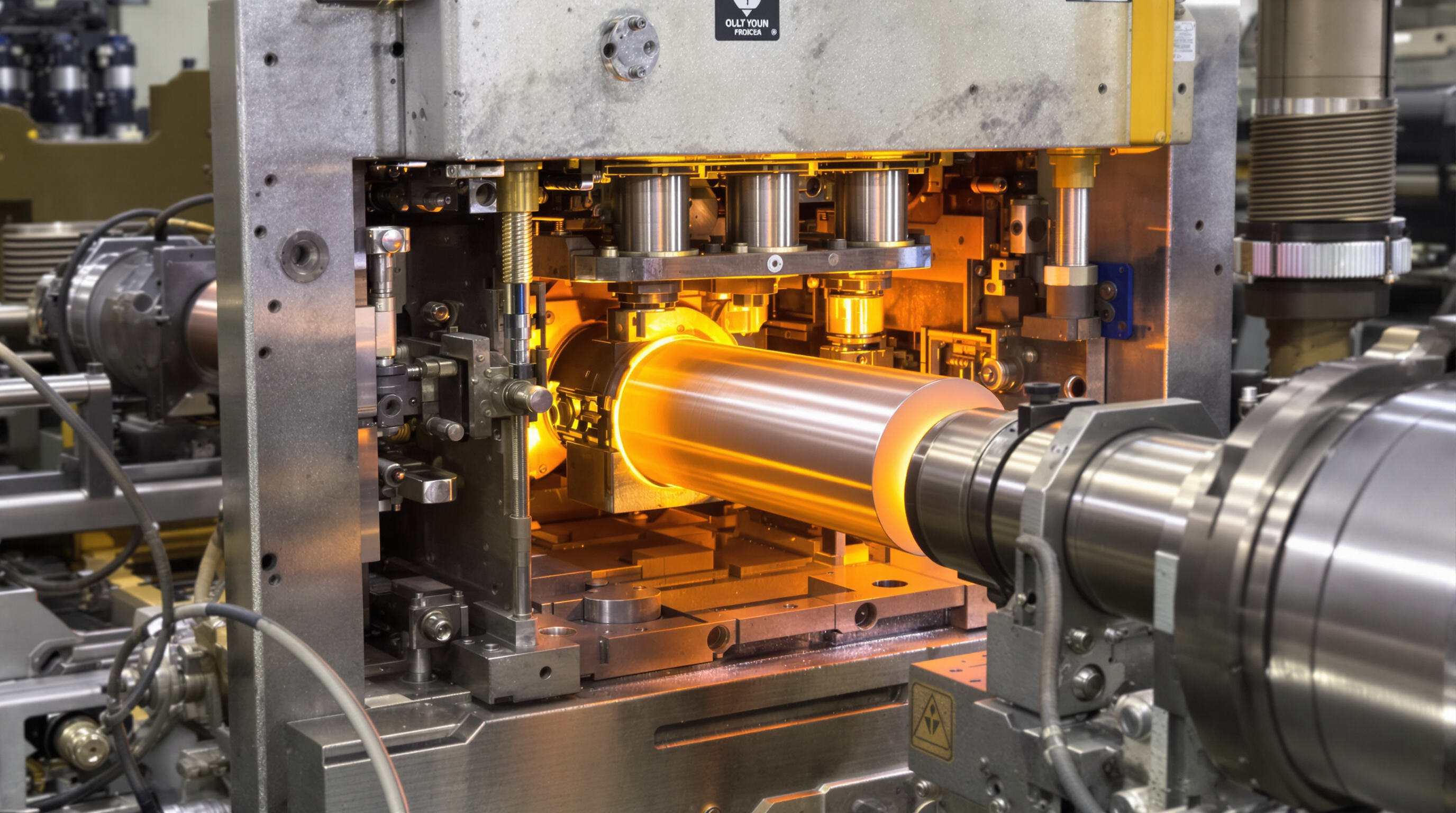

The process begins with heating aluminum billets to 480-500°C, softening the metal for deformation. A hydraulic press then forces the billet through a steel die, shaping it into a continuous profile. After extrusion, the profile is cooled rapidly to preserve its mechanical properties before being cut and treated.

At the heart of extrusion lies the interaction between heat and pressure. Billets heated to optimal plasticity are pushed through custom-designed dies at pressures exceeding 100 MPa. For instance, a billet diameter of 200 mm can produce profiles up to 500 mm in width, demonstrating the scalability of this method.

Aluminum alloys directly dictate a profile’s strength, corrosion resistance, and formability. Alloy 6063, comprising 0.4% silicon and 0.7% magnesium, is widely used for its balanced weldability and thermal conductivity. For high-stress applications, alloys like 7075 (5.6% zinc) are preferred due to their enhanced tensile strength of up to 572 MPa.

Precise control of extrusion parameters ensures consistent quality:

Adjusting these factors by ±5% can reduce energy consumption by 12% while maintaining profile integrity.

The die serves as the blueprint for aluminium extrusion profiles, converting heated billets into precise cross-sectional shapes. Key components include:

Three die types dominate production:

Effective bearing length—the contact area between die and aluminum—proves critical for controlling material flow. Thicker profile sections require longer bearing lengths to equalize extrusion speed with thinner areas, preventing defects like twisting or surface rippling.

Modern CAD software enables micron-level accuracy in die design, with advanced simulations predicting thermal expansion (0.1-0.3% at 450-500°C) and material flow dynamics. Designers prioritize:

Complex multi-void profiles demand nested mandrel systems with thermal compensation features. A 2023 study found optimized die designs reduce material waste by 22% while increasing extrusion press throughput by 15-18% in bridge-type hollow profiles.

Despite advancements, key constraints persist:

| Challenge | Practical Limitation |

|---|---|

| Minimum wall thickness | 0.5mm for 6xxx alloys in standard dies |

| Corner sharpness | Minimum 0.8mm radius for stress distribution |

| Void spacing | 3:1 depth-to-width ratio maximum |

Thin walls below 1mm risk tearing during extrusion, while sharp corners accumulate residual stresses. Multi-chamber profiles require progressive extrusion speeds below 12 m/min to maintain dimensional stability—a 40% reduction compared to single-void extrusions.

Good thermal control is essential for keeping aluminium extrusion profiles intact as they pass through the die during manufacturing. When billets are heated between around 400 and 500 degrees Celsius (the exact range depends on what kind of alloy we're working with), this actually cuts down the extrusion pressure needed by roughly 30 to 40 percent compared to when everything starts at room temperature. Maintaining proper temperature differences across the material helps avoid those annoying surface cracks that happen when metal flows unevenly. It also keeps the cross-section measurements consistent throughout the profile, which matters a lot for parts going into cars or buildings where precision counts. Modern extrusion lines now come equipped with infrared sensors that check billet temperatures in real time, staying within about plus or minus 5 degrees Celsius. This level of monitoring significantly cuts down on wasted materials caused by temperature fluctuations during production.

The 6000 series alloys like 6061 and 6063 need extrusion temps somewhere around 470 to 510 degrees Celsius if we want good ductility without getting into melting issues. Things get different with those stronger 7000 series materials though. They really need careful temperature management between about 380 and 420 degrees to keep the grain boundaries from weakening. Some recent research indicates that cooling down 6082 alloy profiles at roughly 25 degrees per minute after they leave the die can boost their tensile strength by around 15%. When temperatures go outside these recommended ranges, problems tend to start showing up pretty quickly.

Operators adjust parameters dynamically based on alloy-specific phase diagrams to balance production speed (15-50 m/min) with metallurgical requirements.

Extruded aluminium profiles undergo immediate cooling to stabilize their structure. Air cooling is ideal for standard alloys, while water quenching creates rapid solidification for heat-treatable grades, enhancing hardness by 15-20%. This phase determines dimensional accuracy—uneven cooling can introduce residual stresses exceeding 25 MPa in critical sections.

Profiles are stretched by 0.5-3% to align grain structures and eliminate internal stresses. Precision cutting ensures lengths meet tolerances within ±1 mm/m. Advanced laser systems achieve cutting speeds of 12 m/min while maintaining surface roughness below Ra 3.2 µm.

T6 tempering heats profiles to 530°F (277°C) for 4-6 hours, increasing tensile strength by 30-40% compared to untreated alloys. Controlled furnace cooling at 50°F/hour prevents microcracks in complex geometries.

Artificial aging at 320-390°F (160-200°C) for 8-18 hours optimizes precipitation hardening in 6000/7000-series alloys. This process boosts yield strength to 55 ksi (380 MPa) while maintaining elongation rates above 8%—critical for aerospace and automotive applications requiring fatigue resistance.

The right surface treatment can turn ordinary aluminum extrusions into components that really stand up to tough conditions. Take anodizing for instance. This process forms a protective oxide layer using electricity, making the metal much more resistant to corrosion than regular aluminum. Some tests show it can last three times longer before showing signs of wear. Plus, during this same process, manufacturers can add colors that stick around for years without fading. Then there's powder coating, which works differently but offers similar benefits. The coating sticks to the metal via static charge and then hardens when heated, creating a finish that resists both sun damage and scratches. Real world testing shows anodized surfaces can survive over two thousand hours in salt spray chambers according to ASTM standards, and they keep their color integrity for decades. That's why we see these treatments so often in places where things get really harsh, whether it's buildings near the ocean or equipment used in chemical plants. The initial investment pays off big time because these treated parts need far less maintenance over their lifespan.

Industrial sectors leverage extrusion's design flexibility to create purpose-built aluminium solutions meeting precise spatial, functional, and regulatory requirements. Key customization approaches include:

The manufacturing sector achieves 15-25% material savings through topology-optimized extrusion designs, while construction benefits from integrated thermal barriers enhancing energy efficiency. Secondary machining further differentiates profiles through precision-cut features like threading or mounting interfaces. This adaptable engineering approach enables application-specific innovation across industries.

The aluminium extrusion process is a thermomechanical method that transforms cylindrical aluminium billets into cross-sectional profiles used in various industries, like construction and automotive.

Alloy selection is crucial as it dictates a profile's strength, corrosion resistance, and formability. Different alloys are chosen based on the application's stresses and requirements.

Proper temperature control and heating ensure that the extrusion process maintains the integrity of the aluminium profiles, preventing defects like surface cracks and ensuring consistent cross-section measurements.