Aluminum alloy profiles come in various shapes that get either extruded or formed through processes where aluminum is mixed with other elements to boost its physical characteristics. What goes into making these alloys really matters when it comes to what they can be used for. We see them everywhere from aircraft structural components all the way down to residential window frames. Research in material science shows something interesting happens when manufacturers add just 1 to 5 percent of certain metals like copper, magnesium, or silicon to the mix. The result? Tensile strength jumps anywhere between 200 to 400 percent over regular aluminum. That kind of customization lets designers tweak the profiles so they work better under stress, resist rust longer, and still remain easy to work with during production.

Primary alloying elements serve distinct roles:

| Element | Primary Function | Common Alloy Series |

|---|---|---|

| Copper (Cu) | Enhances strength via precipitation hardening | 2xxx (e.g., 2024) |

| Magnesium (Mg) | Improves weldability and strain resistance | 5xxx, 6xxx |

| Silicon (Si) | Increases fluidity for extrusion processes | 4xxx, 6xxx |

| Zinc (Zn) | Boosts ultimate tensile strength | 7xxx (e.g., 7075) |

Manganese and chromium are often added in smaller quantities (<1%) to refine grain structures or improve stress corrosion resistance.

The interaction between elements creates synergistic effects. For example:

Each series represents a deliberate compromise between machinability, environmental resilience, and load-bearing capacity.

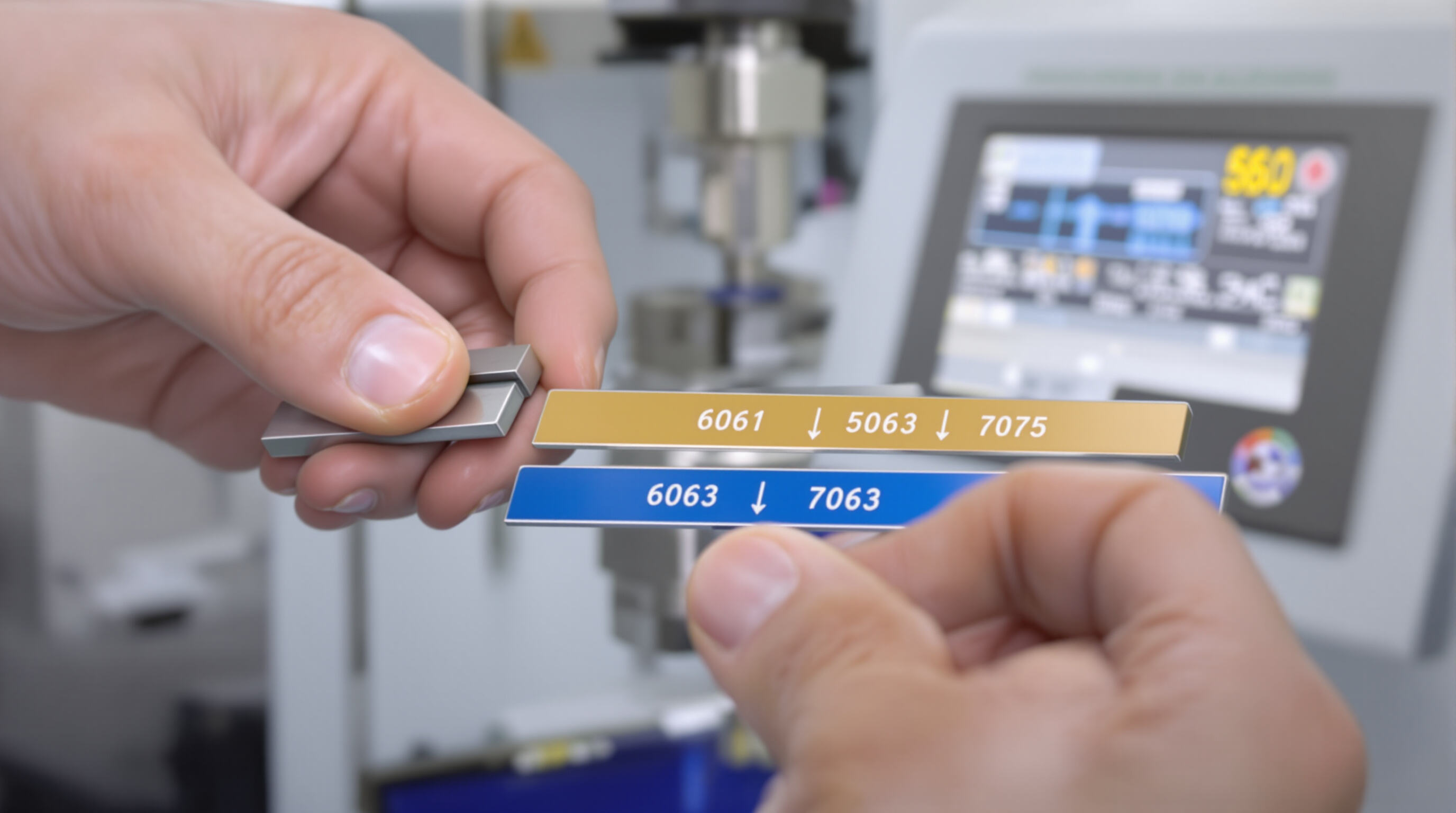

Aluminum alloy profiles show quite different tensile strengths depending on their grade. Take 7075-T6 for instance, which has an impressive range of 540 to 570 MPa. That puts it about half again as strong as 6061-T6 alloys that measure between 240 and 310 MPa, and almost twice as tough as the 6063-T5 grade at around 175 to 215 MPa. These strength differences matter a lot when choosing materials for specific jobs. The aerospace industry relies heavily on 7075 for critical wing parts because of this superior strength. Meanwhile, boat builders often go with 6061 for marine frames where corrosion resistance matters as much as strength. Architects tend to prefer 6063 for things like window frames and other structural elements that don't need extreme load bearing capacity. How these alloys are treated after manufacturing makes a big difference too. When 6061 gets artificial aging instead of just sitting around naturally, its yield strength goes up by roughly 30%, which explains why many manufacturers bother with the extra step despite the added cost.

How well aluminum resists corrosion really comes down to what other metals get mixed into it. Take the 6xxx series like 6061 and 6063 — these alloys form magnesium silicide which gives them great protection against atmospheric corrosion. That's why we often see them used in buildings near the coast where salt air would eat away at other materials. On the flip side, 7075 aluminum has lots of zinc in it, so when exposed to saltwater environments, it needs extra protection through coatings or paint jobs. When looking at thermal conductivity, things work almost backwards. The 6061 grade conducts heat pretty well at around 167 watts per meter Kelvin, making it good choice for things like computer heat sinks. But 7075 isn't as effective with only about 130 W/mK. If someone wants maximum conductivity, pure aluminum from the 1xxx series hits 220 W/mK, but honestly, nobody uses this stuff much because it doesn't hold up mechanically under stress.

Weight-to-strength ratio has become a key consideration in modern engineering design, and here aluminum alloys really shine over steel, often delivering performance improvements around 200 to 300 percent better. Recent research from 2023 shows how specific grades like 7075 aluminum hit about 175 MPa per gram per cubic centimeter, whereas stainless steel only manages around 62 MPa in the same measure. No wonder aerospace companies have been swapping out steel fasteners for these high performance aluminum parts lately. The switch typically cuts down on overall weight by roughly 40 percent while still holding up under shear stress. Even in automotive applications we see this trend continuing, with many manufacturers turning to forged 6061 aluminum for brake calipers. This change helps reduce what engineers call unsprung mass by about 35 percent when compared to traditional cast iron alternatives, which makes a real difference in vehicle handling and fuel efficiency.

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Thermal Conductivity (W/m·K) |

|---|---|---|---|---|

| 6061-T6 | 240—310 | 145—275 | 7—15 | 167 |

| 6063-T5 | 175—215 | 110—190 | 6—12 | 201 |

| 7075-T6 | 540—570 | 470—505 | 2—10 | 130 |

This table highlights key trade-offs: higher strength correlates with reduced ductility and lower thermal performance. Engineers select alloys based on priority—7075 for maximal load-bearing, 6063 for thermal management, and 6061 for balanced characteristics.

Aluminum alloy profiles today can create really intricate shapes thanks to these fancy extrusion techniques. Most manufacturers still rely on hot extrusion methods where they heat up those aluminum billets and push them through specially designed dies at around 450 degrees Celsius or so. This process works great for making all sorts of complicated structures including hollow sections, multiple chamber designs, and those super thin walls needed for things like solar panels and electric vehicle battery cases. According to recent data from the 2024 Automotive Aluminum Applications Report, the latest improvements in die technology have gotten pretty impressive too. We're talking about achieving tolerances as tight as plus or minus 0.1 millimeters on parts that need to handle serious stress in cars these days.

Material engineers optimize aluminum alloys by adjusting magnesium (0.5—1.5%), silicon (0.2—0.8%), and zinc (4—6%) concentrations based on performance needs. Architectural profiles use corrosion-resistant 6063-T6, while aerospace applications require high-strength 7075-T651 with 540 MPa tensile strength. Strategic alloy customization reduces material waste by 18—22% compared to generic approaches (International Aluminum Institute 2023).

Post-extrusion treatments significantly enhance profile performance:

When combined with CNC machining, these processes help aluminum profiles meet ISO 9001:2015 standards while maintaining over 95% recyclability across industries.

Aluminum alloy profiles really stand out when it comes to structural performance in today's buildings because they resist corrosion so well and offer great strength without all the extra weight. Many architects have started incorporating these profiles into their projects for things like curtain walls, solar shading solutions, and even modular framing systems. They love how flexible these materials are for design purposes plus they basically take care of themselves over time. This combination of benefits has driven quite a surge in demand actually. The World Architecture Census reports that the global market for aluminum in construction has grown about 22% since 2022. What makes these profiles particularly appealing from a sustainability standpoint is their contribution to energy efficiency. When used in thermally broken window systems, they can cut down on HVAC loads anywhere between 15% to 30% compared with what we see from traditional building materials.

Using lightweight aluminum alloys makes transport much more efficient. When vehicles get lighter by around 10%, fuel consumption drops between 6 and 8 percent according to SAE research from last year. Car manufacturers often turn to 6000 series alloys when building parts like crash management systems and electric car battery casings. Meanwhile, the aviation industry prefers stronger materials like 7075 grade aluminum for critical structural elements such as airplane wings and landing gear structures. These weight reductions have had real impact too - newer Airbus A350 planes produce about 25% fewer emissions per passenger mile compared to older aircraft models. As environmental regulations tighten across industries, we're seeing more companies adopt extruded aluminum parts for their chassis designs because they can cut down on carbon footprint while still keeping everything safe enough for daily use.

These days, most renewable energy setups depend on extruded aluminum profiles because they hold up so well against tough environmental conditions. Take wind turbines for instance their blades often feature aluminum spar caps which cut down weight without sacrificing rigidity. According to research from NREL published last year, this design tweak actually boosts energy output around 8%. When it comes to solar farms, engineers prefer mounting systems made from 6063-T5 alloy racks since these materials resist both saltwater damage and harmful UV rays over time. Looking at newer developments in ocean energy, we see similar trends emerging with tidal power platforms relying heavily on special marine grade aluminum for everything from buoyancy chambers to supporting structures. Industry reports suggest demand for aluminum components across all forms of green infrastructure could grow at an impressive rate of nearly 18% each year until 2030 as companies continue investing in sustainable solutions.

What makes aluminum so sustainable is how easily it can be recycled again and again. When we melt down old aluminum, it takes just about 5 percent of what would be needed to make new stuff from scratch. Pretty impressive right? Around three quarters of all aluminum made over history is still being used somewhere today, creating almost a complete circle of materials. Studies looking at the whole life cycle of aluminum products reveal something shocking too. Recycled aluminum produces roughly 95 percent less carbon dioxide compared to making it fresh from bauxite ore according to industry reports from 2023. Even when buildings get torn down or cars reach their end of days, those aluminum parts keep their worth. We're talking about around 50 million tons kept out of landfills every year. With this kind of reuse potential, aluminum plays a big role in helping manufacturers hit those tough net zero targets they've been setting lately.

Aluminum alloy profiles commonly include elements like copper, magnesium, silicon, and zinc, each contributing distinct properties such as strength, weldability, and corrosion resistance.

The weight-to-strength ratio is crucial as it allows aluminum alloys to deliver significant performance improvements over other materials like steel, leading to reduced weight in engineering applications without compromising strength.

Aluminum recycling is quite sustainable as it requires only about 5% of the energy compared to producing new aluminum from ore, significantly reducing carbon emissions and conserving resources.

Applications such as aerospace, automotive, construction, and renewable energy systems benefit from aluminum alloy profiles due to their strength, corrosion resistance, and lightweight properties.