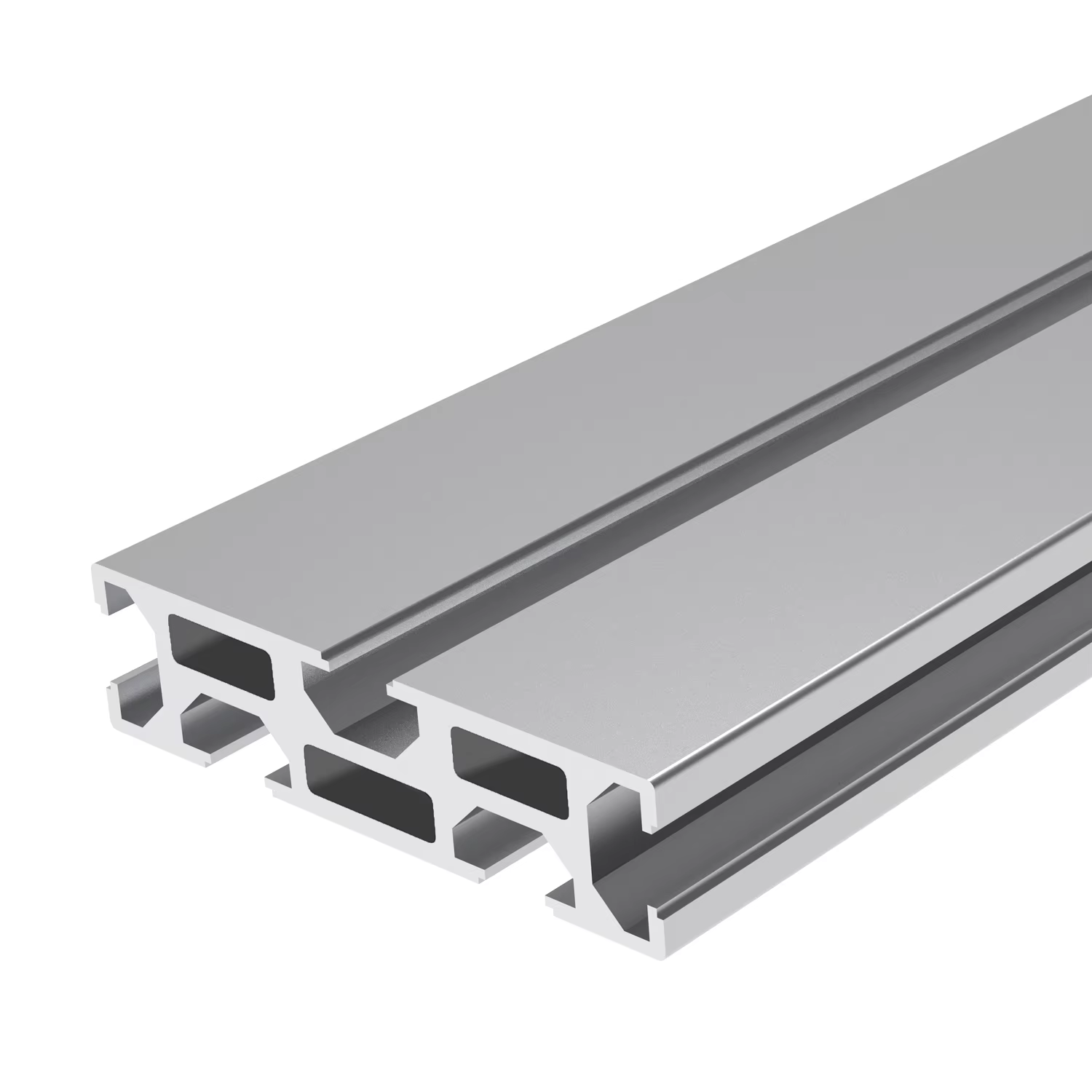

80/20 aluminum extrusion refers to a framing system that uses T-slot profiles for quick assembly and easy reconfiguration without needing welders or drills. Manufacturers heat up 6105-T5 aluminum alloy, which has about 35,000 psi tensile strength plus good corrosion resistance properties, then push it through special dies to make standard profiles with those handy T-slots built right in. What makes these systems so useful? Those slots act as mounting spots throughout the entire profile length. Workers can attach bolts, install brackets, or mount various accessories wherever needed simply by sliding them into place. No more measuring exact positions or making holes ahead of time.

The term "80/20" actually comes from what's called the Pareto principle. Basically, most of the structural flexibility we see ends up coming from only about 20% of all the parts used. When it comes to manufacturing profiles, companies stick to standard dimensions like 25 by 25 millimeters or 40 by 40 millimeters. These have really tight tolerances sometimes down to plus or minus 0.1 mm which means they fit together consistently no matter where they're made. What makes these profiles work so well is the special 6105-T5 alloy that contains magnesium and silicon. This combination allows for easier machining without sacrificing strength, which is why engineers often choose them when building structures that need to support weight.

T-slots turn simple aluminum bars into versatile building blocks. A single 40x40mm profile supports:

Advanced die engineering and real-time thermal monitoring during extrusion prevent warping, achieving cross-sectional accuracy within 0.2mm/m. This ensures connectors and accessories like corner brackets and linear bearings fit reliably across batches and over time. Post-extrusion anodizing adds a 15–25um oxide layer, doubling scratch resistance compared to raw aluminum.

The 80/20 aluminum extrusion system has become a go to solution for building sturdy frames across various industrial applications like presses, CNC machines, and conveyor belts. What makes this work so well? The 6063-T5 aluminum grade offers an impressive strength to weight balance. These frames can actually hold weights around 30 thousand pounds yet still stand up against rust even when exposed to tough conditions on factory floors. A recent look at industrial automation from 2023 found something interesting too. When manufacturers switched from welding steel to using extruded aluminum frames, they saved roughly 40% of their assembly time. That kind of efficiency boost explains why so many production facilities are now favoring aluminum over traditional materials for their moving parts and structural components.

Manufacturers use T-slot profiles to build adjustable-height workstations that enhance operator comfort and efficiency. These modular setups can integrate power strips, tool holders, and anti-fatigue matting while meeting ISO 14122 safety standards. Automotive plant audits have shown productivity gains of 18–22% after transitioning to adaptable workspaces.

T-slot compatibility with polycarbonate panels and interlocking hardware allows quick deployment of OSHA-compliant machine guards. These barriers are 60% lighter than steel equivalents yet meet ANSI B11.19 impact resistance requirements, reducing injury risks near robotics and stamping equipment.

A 2023 Industry Automation Report found that 63% of manufacturing facilities now standardize on 80 20 aluminium extrusion for workstation construction—a 17% increase since 2020. Key benefits include $12,000 in annual maintenance savings per station and the ability to reconfigure layouts in under four hours during product changeovers.

The 80/20 extrusion system strikes just the right mix between being sturdy enough for industrial applications while still keeping things light. Most engineers reach for those T-slot profiles when they need to install linear guides and actuators because these components stay aligned even after thousands of cycles. When building conveyor belts with this aluminum framework instead of traditional steel, manufacturers typically see around a 40 percent drop in overall weight. But here's what really matters: despite weighing less, these systems can handle the same heavy loads. This means production lines run quicker since machines don't have to work as hard, and energy bills go down too. Pick and place robots on assembly lines benefit especially well from this setup, making packaging operations much more efficient across the board.

When production lines need updating, these flexible T-slot profiles make it much easier to adjust safety systems quickly. Things like machine guards, light curtains and those emergency stop bars can just be moved around or put in place with standard parts instead of custom fabrication. Shops that have switched to these modular aluminum barriers tell us they spend about two thirds less time offline when making changes compared to facilities still stuck with old welded steel setups. And bonus? They stay compliant with those important ISO 13857 requirements throughout the whole process.

One major car manufacturer in Europe swapped out their traditional steel mounts for frames made from 80/20 extrusions when setting up their welding robots. What used to take workers three whole days of cutting and rewelding whenever they needed to adjust those robotic arms? Now it's down to about two hours total. Think about what that means over time. Just looking at the numbers from the past year and a half shows something pretty impressive happened here. The factory saved around 1,200 man hours that would have otherwise been lost during production stops. And guess what? Their yearly production numbers went up by nearly 9 percent as a result of all these changes. Makes sense really, when equipment can be reconfigured so quickly instead of tearing everything apart each time there's a need for adjustment.

Pre-engineered extrusion kits are streamlining integration of IoT-enabled equipment. Factories adopting these ready-to-deploy framing solutions report 35% faster automation upgrades—accelerating the transition to Industry 4.0 capabilities without extensive retrofitting.

Many makers and engineers turn to 80/20 aluminum extrusion when they need something precise, tough, and adaptable for their projects. Around most maker spaces, these T-slot profiles show up everywhere from custom workbenches to CNC machine frames and even those neat modular storage systems everyone seems to want these days. The prototyping labs really get creative with them too building everything from basic test rigs to sophisticated optical mounts and full fledged robotics platforms. For folks working at home workshops, the lightweight nature makes these extrusions perfect for storage racks, those fancy smart home control boxes, and adjustable standing desks that can be tweaked whenever inspiration strikes or space requirements shift.

Aluminum extrusions are about 30 percent lighter than steel while still holding up pretty well for most home projects around the workshop. What makes them really handy is that T-slot design which lets folks put things together without needing special tools just regular screws and bolts will do the trick. And if something needs changing later on, there's no need to take everything apart completely. These connections stay intact between different builds, so they save money over time when working on several projects in a row. Some research shows these modular T-slot systems cut down building time by roughly 40% when compared to traditional ways of making stuff, though results might vary depending on what exactly someone is trying to construct.

To maximize longevity and flexibility, designers recommend: