Aluminum profile 40x40 gets its name from that familiar 40mm by 40mm cross section, which fits right into standard metric T-slot systems used across manufacturing. When it comes to extrusion quality, most manufacturers stick with ISO 2768 standards, keeping those dimensions pretty tight within about plus or minus 0.2mm. That level of accuracy matters a lot when building modules that need to snap together perfectly every time. Nearly all these profiles come equipped with those 8mm wide slots running along them, plus a central hole sized just right for M8 bolts. This design makes connecting everything from automated machinery parts to structural supports much simpler on the factory floor.

When checking measurements, digital calipers are the go-to tool for getting accurate readings on width, height, and how things line up diagonally across different spots. With structural parts, it's important to check wall thickness in multiple places since even small differences beyond 0.15mm tolerance can really impact how well something holds up under stress. Most shops that run through more than 50 pieces regularly switch to laser scanners these days. Not only does this speed things up, but it also keeps everything within those strict ISO 9001:2015 requirements that so many manufacturers have to follow for quality control.

Standard 40x40 profiles are available in wall thicknesses ranging from 1.5mm to 3.0mm:

Thicker walls reduce deflection by up to 32% under bending stress, according to the 2023 Materials Performance Report, though they increase material costs by 18–25%.

Standard 8mm T-slots work well with M8 bolts as well as DIN compliant connectors, which makes it possible to quickly adjust machine guards, test setups, and automated systems when needed. The center bore dimensions range from approximately 6.8 to 7.0 mm, just right for fitting those threaded inserts that ensure proper vertical load distribution across components. For end caps, we're looking at very tight tolerances around ±0.1 mm. These small but important details stop dust and other particles from getting inside, so these profiles find their place in cleanrooms and other manufacturing areas where contamination control is absolutely critical.

Most 40x40 aluminum profiles get made from 6063-T5 alloy, which contains magnesium and silicon. This particular blend works really well when shaping because it maintains consistent structure throughout the process. The material hits around 186 MPa in tensile strength while conducting heat exceptionally well too. That makes it great choice for applications where temperature control matters most. Plus, since it welds nicely and flows through extrusion machines efficiently, manufacturers can create all sorts of complicated shapes without worrying about compromising the strength properties that make this alloy so popular across various industries.

When left exposed to air, aluminum creates its own shield against rust through a thin oxide film that develops naturally on the surface. The process called anodizing takes this natural defense mechanism one step further by building up that oxide layer to between 5 and 25 microns thick. This makes the material much harder to scratch and gives it better protection from sunlight degradation over time. For even greater longevity, many manufacturers apply powder coatings which have been shown to withstand salt water exposure tests for over 1,000 hours according to industry standards. Beyond just making things last longer, these surface treatments open up all sorts of possibilities when it comes to coloring metal components for buildings or creating distinctive brand identities across different products.

Aluminum profiles measuring 40x40mm have a density around 2.7 grams per cubic centimeter, which makes them roughly one third lighter than steel. These profiles can handle industrial weights ranging from 200 to 500 kilograms without adding too much extra weight to structures. Because they offer such good strength relative to their weight, engineers can build taller frames that need less robust foundations. This is especially useful for things like automated conveyor belts in manufacturing plants. When tested using computer modeling techniques called finite element analysis, these profiles show very little bending even when subjected to normal working conditions. Measurements typically stay below 1.5 millimeters of deflection per meter, which means they maintain their shape and stability over time.

The 40x40 aluminum profile delivers strong load-bearing performance through optimized geometry and material engineering. Standard 6063-T5 alloy variants withstand tensile stresses up to 172 MPa, while 6061-T6 versions offer compressive strengths as high as 262 MPa–key for demanding applications like robotic arms and heavy-duty conveyors.

Field evaluations on modular assembly platforms show that 3mm-wall 40x40 extrusions perform reliably under various loads:

| Load Type | Max Capacity | Deflection Limit |

|---|---|---|

| Static | 220 kg/m | 2.8mm at 150 kg |

| Dynamic | 130 kg/m | 1.2mm at 80 kg |

These results confirm suitability for industrial frameworks requiring deformation ratios no greater than 1:500. Engineers typically apply a 2.5x safety factor to account for variable stresses, preserving the profile’s lightweight advantage with an average weight of 2.7 kg/m.

Industrial automation relies heavily on the 40x40 aluminum profile when building frames for things like robotic arms, conveyor belts, and those linear motion guides we see everywhere on factory floors. What makes this profile so popular? Well, it has that square cross section plus those handy T-slots built right in, which means engineers can create really precise structures that hold up against all sorts of vibrations and mechanical stress. The walls are usually around 1.8 to 3 millimeters thick, and interestingly enough, these profiles stay aligned pretty well too, with tolerances staying within about half a millimeter per meter. They're strong enough to support machine guards and can handle weights going up to roughly 740 kilograms, making them a workhorse component in many manufacturing environments.

Forty-millimeter aluminum profiles dominate flexible manufacturing setups due to their tool-free assembly using T-slot nuts and brackets, availability of over 180 compatible connectors, and adaptability to panels, screens, and casters. This modularity allows facilities to reconfigure workstations–from electronics assembly to inspection zones–within 48 hours, significantly improving operational agility.

When architects need materials that won't rust and stay light, they often turn to those 40x40 aluminum extrusions for things like truss systems, mounting brackets for solar panels, and supporting structures on building exteriors. The powder coating makes these profiles really tough against corrosion too. These coated versions can last well past 1,500 hours in salt spray tests according to ASTM standards, which is pretty impressive compared to regular steel options. Plus, using aluminum cuts down on overall weight by about two thirds, making transportation and installation easier. We've seen some interesting real world applications lately including massive retail display structures with 8 meter long cantilevers extending from walls, office spaces where acoustic panels are built right into partition systems, and entire framework solutions for commercial LED lighting installations across large facilities.

The 40x40 aluminum profile combines industrial strength with design versatility, establishing it as a foundational material in manufacturing, automation, and modern construction.

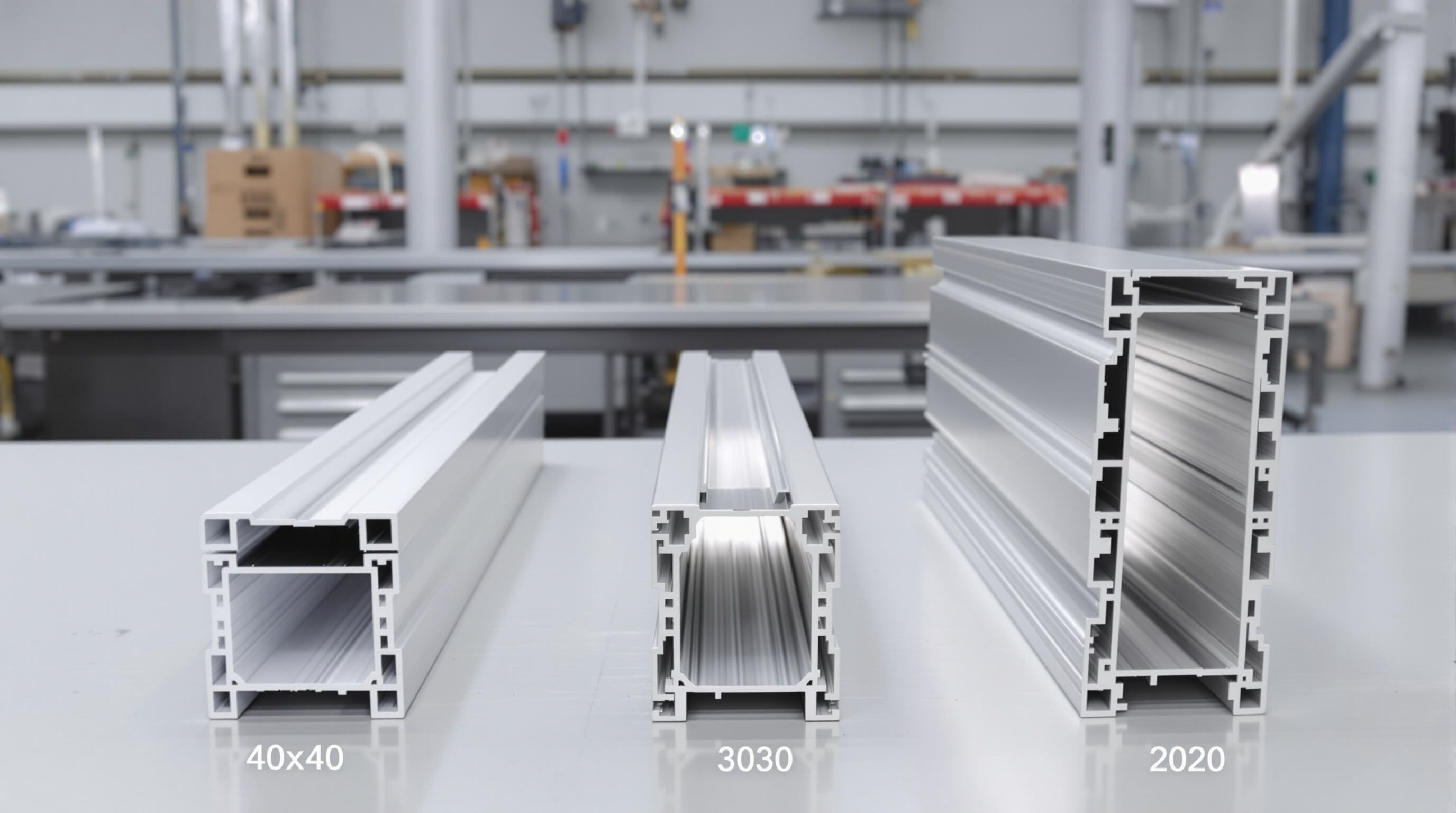

The 40x40 aluminum profile offers significantly greater rigidity than smaller counterparts: its 40mm x 40mm cross-section provides four times the structural stiffness of 2020 profiles (20mm x 20mm) and 77% more than 3030 profiles (30mm x 30mm). Key differences include:

The 40x40 profile supports 20–30% more accessory configurations than 2020 or 3030 due to its wider 8–10mm T-slots. This allows simultaneous mounting of sensors, brackets, and pneumatic lines without interference–essential for scalable automation. Compared to 2020 frames that often require reinforcement, 40x40 reduces assembly time by 35% in complex installations.

Choose based on application demands:

The price tag on 40x40 is definitely steeper than 3030, coming in at around 25 to 40 percent more per meter. But what makes it worth considering is how much longer it lasts under heavy use conditions. We're talking about almost double the service life before needing replacement. When looking at bigger installations over 50 meters in length, there's another advantage too. The 40x40 profile needs about half as many support brackets compared to the 2020 version. This cuts down both materials needed and labor time significantly, saving somewhere between 18 and 22 percent overall. For systems that stay put for years without changes, most professionals will tell you that those savings add up fast enough to make the extra upfront cost worthwhile in the long run.