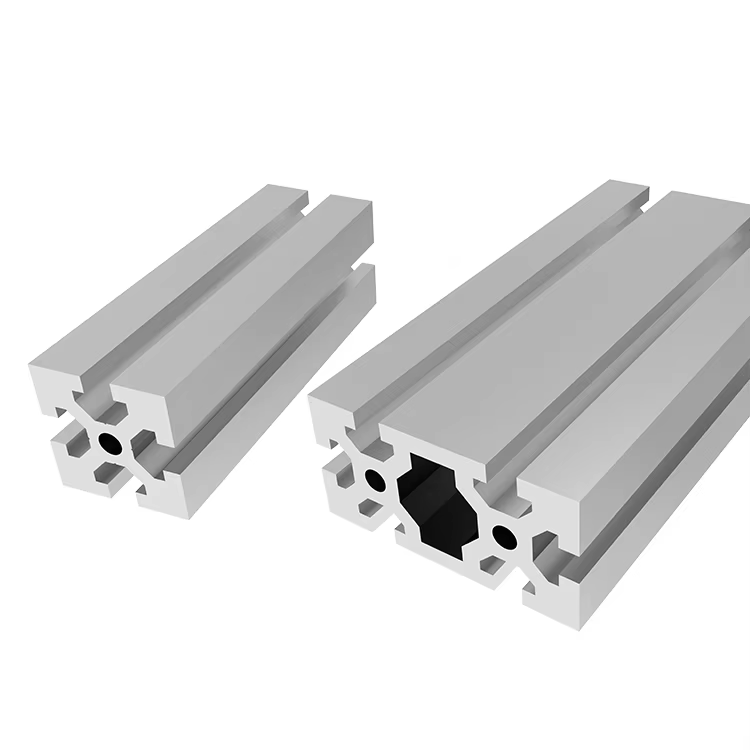

T slot aluminum basically means those metal profiles that have these long T-shaped grooves running down their sides. This design lets people assemble things together using bolts instead of welding everything permanently. Most factories rely on these standard parts for building all sorts of stuff like industrial frames, workbenches, and automated machinery setups. What makes them so useful compared to traditional welding methods? Well, the slots let workers move around brackets, attach panels wherever needed, and install various accessories without having to drill holes or make irreversible changes to the structure. Pretty handy when adjustments are needed later on.

Most profiles are made from 6000-series aluminum alloys such as 6061-T6 or 6063-T5, selected for their excellent balance of strength, machinability, and corrosion resistance. During extrusion, heated aluminum billets are forced through precision dies at 400–500°C (752–932°F), producing consistent cross-sectional shapes. Key design features include:

| Property | Aluminum 6063-T5 | Mild Steel | Advantage |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 7.85 | 66% lighter |

| Tensile Strength (MPa) | 241 | 370 | 65% of steel |

| Corrosion Resistance | High (anodized) | Low (untreated) | No painting needed |

Aluminum’s natural oxide layer provides durable, maintenance-free protection in humid or corrosive environments. Its full recyclability enables up to 95% energy savings compared to primary production, according to the Aluminum Association (2022), making it a sustainable choice for industrial construction.

The numbers 1010, 2020, 3030, and 4040 actually refer to the size measurements of these profiles in millimeters. Take the 1010 series for instance, it's basically 10 by 10 mm in dimension. These smaller profiles work great for things that don't need much support like display stands or laboratory equipment where they can handle weights around 50 kilograms without bending. Moving up to the 2020 profiles at 20 by 20 mm gives us something stronger yet still manageable. Many manufacturers use these in their CNC routers and conveyor systems because they can take on loads up to 200 kg before showing any signs of strain. When we get to the bigger sizes like 3030 and 4040, these really shine in industrial settings. They're built tough enough for machine bases and robotic arms, capable of withstanding moving loads exceeding 500 kg. What makes them special is how stable they stay even when stressed out, keeping shape variations below half a millimeter per meter throughout operation.

When it comes to structural performance, engineers focus on two main factors: area moment of inertia (I) and torsional constant (J). The moment of inertia basically tells us how resistant something is to bending forces. Take 4040 profiles for instance they have an I-value that's actually four times what we see in 2020 equivalents. Now looking at torsion, the torsional constant (J) shows how well materials resist twisting. Profiles from the 3030 series deliver about double plus twenty percent more rotational stability compared to those old 2020 models. This matters a lot when dealing with cantilevers or structures that aren't symmetrical since these designs need extra strength against twisting forces.

Getting the right balance between how strong something is and how much it weighs matters a lot in engineering design. Take those 4040 profiles for instance they're super stiff at around 17.5 kN per millimeter but weighing in at 4.2 kilograms per meter can get pretty heavy when we need something that moves around easily. Most engineers tackle this problem by using 4040 material for the main frame while saving the lighter 2020 profiles for upper parts of the structure. This combo typically cuts down on overall weight by about two thirds without messing up the load distribution across the whole system. And if budget allows, going for advanced alloys such as 6063-T6 makes things even better since these materials pack roughly 25 percent more strength compared to regular grades while keeping the same weight characteristics. Makes sense why so many manufacturers are making the switch nowadays.

T slot aluminum systems make it easy to reconfigure things quickly because they're built with a modular design. The components fit together anywhere along those T shaped grooves, so there's basically no limit to how many times we can adjust them without weakening the structure. These aren't like welded frames where cutting something out means destroying it completely. With T slot systems, parts come apart cleanly and get reused again and again. According to a recent industry report from last year, around 8 out of 10 manufacturers who switched to modular framing saw their retrofitting expenses drop somewhere between 40 percent and almost two thirds when compared to old school methods. And since aluminum itself is about 95% recyclable, all this reuse really helps companies run things in a greener way while still keeping costs down over time.

T slot systems basically cut out welding altogether, which means companies don't have to hire those expensive welders anymore and nobody gets exposed to all those nasty fumes. The connectors just slip right into place and lock tight in no time at all. No more worrying about heat warping things or getting that perfect weld every single time. Some tests found buildings go together about half as fast compared to traditional steel welding methods, plus everything lines up pretty much spot on, within like half a millimeter either way. Plus there's way less mess involved. No sparks flying around, no paint overspray everywhere. All this adds up to saving money too. Companies spend roughly 30 percent less overall because they rent fewer tools and don't have to deal with all those OSHA paperwork headaches that come with welding operations.

When it comes to finishes, anodized aluminum profiles offer something pretty special - they come in matte black, silver tones, or even custom colors that really stand out. These aren't just any old surfaces though. Compared to regular painted steel, anodized ones actually hold up better against chips, harsh chemicals, and those pesky UV rays that can fade everything else. That's why so many manufacturers love them for cleanroom settings or anywhere under FDA regulations where appearances matter as much as performance. A recent survey from last year showed something interesting too. More than seven out of ten system integrators said their clients were going crazy for that modern "industrial-chic" look of T-slot framing instead of seeing all those ugly weld seams sticking out everywhere. And let's not forget about those built-in channels that hide away all sorts of messy wiring and pneumatic lines. What does this mean? Workspaces end up looking way neater without all the clutter hanging around.

The durability of joints comes down to materials like 6063-T5 alloy, known for reaching tensile strengths above 160 MPa while keeping a solid 12:1 strength to weight ratio. When working in places where moisture or chemicals are present, anodized finishes become really important for stopping corrosion damage. Anyone designing structures needs to think about the area moment of inertia when picking out profiles for their projects. Take a look at what structural engineers found recently: a 45 by 45 mm profile with extra reinforcement in the webbing can handle around 4.8 kN of force before bending beyond acceptable limits. That's actually about 62 percent improvement compared to regular designs we typically see on the market today.

Most industrial setups go with safety margins somewhere between 3:1 and 5:1 when dealing with dynamic loads. Take the 4040-series profiles as an example they're generally rated at around 2,400 Newtons for static loading but will handle about 600 Newtons dynamically provided all the joints line up correctly. When designing these systems, engineers look closely at material properties like yield strength which stands at approximately 110 MPa for 6063-T5 aluminum alloy, along with ultimate tensile strength numbers to ensure components won't deform permanently under stress. And let's not forget about thermal expansion either. Aluminum expands quite a bit when heated up its coefficient is roughly 23.6 micrometers per meter per degree Celsius. That means manufacturers need to incorporate expansion joints or install floating mounts wherever there might be significant temperature changes during operation otherwise the accumulated stresses could cause serious problems down the road.

Deflection in t slot beams is calculated using:

I' = (F × L³) / (3 × E × I) Where:

For a 1,200 mm span under 500 N, a 3030 profile (I = 21,500 mm⁴) deflects 2.3 mm—within acceptable industrial tolerances. Adding gusset plates reduces deflection by up to 40%, demonstrating how reinforcement improves stability.

Getting things aligned properly makes sure weight spreads out evenly across structures and stops those annoying stress points from forming. When putting stuff together, good old laser levels work wonders alongside digital protractors that can measure within half a degree. Diagonal bracing really boosts how stiff something is against twisting forces, sometimes by as much as 40%. This matters a lot in places where there's constant vibration going on. Pairing 2020 or 3030 profiles with those metal gusset plates gives the best results we've seen so far. Mounting sensors or actuators? Standardized M6 threads or 1/4"-20 slots are your friends here since they play nicely with most industrial equipment out there. And don't forget about matching up the profile's area moment of inertia with what kind of bending forces it will face. Doing this keeps unwanted sagging under control, ideally keeping deflection below just 0.2% of whatever distance we're talking about.

Corner brackets that have been reinforced with three axis adjustability help get things aligned properly and spread out those shear forces so they don't concentrate too much on any one spot. When dealing with cantilevered loads, triangular joints actually change how the force works, turning bending stress into compression which makes everything much more stable overall. By alternating the slots where T-nuts go, we create multiple pathways for the load to travel through, which means these joints last about 2.8 times longer when subjected to repeated cycles of stress compared to regular single plane connections. And for equipment that moves around or vibrates constantly, it's really important to use some kind of thread locking compound because otherwise those bolts tend to work themselves loose after a while no matter what.