What makes 6060 aluminum so versatile? Let's look at the numbers: around 97.2% aluminum as the base material, plus between 0.35 to 0.6% magnesium and similar amounts of silicon. The magnesium content actually boosts mechanical strength through what's called solid solution hardening. Silicon plays a different role by improving how well the metal flows when being extruded, which helps create those consistently thin walls we see in many products. With this mix, 6060 manages to stretch about 12% before breaking, which works great for things that need to be shaped but still hold their structure. Compared to other alloys with more silicon, 6060 isn't all about maximum strength. Instead, it focuses on resisting cracks, especially important when working with complicated bends or shapes that might otherwise cause fractures in weaker materials.

| Property | 6060 Aluminum | 6063 Aluminum | 6005 Aluminum |

|---|---|---|---|

| Silicon Content | 0.3–0.6% | 0.4–0.8% | 0.6–0.9% |

| Magnesium Content | 0.35–0.6% | 0.6–1.0% | 0.4–0.7% |

| Typical Yield Strength (T5 Temper) | 150 MPa | 215 MPa | 195 MPa |

| Key Advantage | Superior cold forming | Better anodized finish | Higher load capacity |

When looking at the 6060 alloy versus 6063, there's definitely a trade off here. The tensile strength drops by around 15% in T5 temper condition, but what we gain is much better extrudability - about 20% improvement makes all the difference for complex shapes and detailed profiles. What sets it apart from 6005 aluminum is the silicon content. With a tighter silicon range, dies last longer during production runs. The 6005 needs more silicon to hit those automotive standards for stiffness, which actually increases tool wear over time. Many architects go with 6060 specifically for buildings near saltwater areas where both shape precision matters and corrosion resistance is critical. Coastal structures need materials that hold up against moisture without losing their structural integrity.

The properties of 6060 aluminum extrusions change noticeably depending on their temper state. When in T4 condition after natural aging, this alloy typically reaches around 160 to 180 MPa for tensile strength, along with about 14 to 18% elongation. This gives it enough strength for many applications while still allowing some degree of cold forming. Moving to T5 temper involves controlled cooling processes that boost yield strength up to approximately 130 MPa. For maximum performance, the T6 temper comes into play where artificial aging pushes tensile strength even higher, reaching between 190 and 210 MPa. What makes these differences possible? The formation of magnesium silicide precipitates plays a big role here. Research into various 6000 series alloys consistently shows how these microscopic changes translate into better mechanical properties, which explains why architects and engineers often specify different tempers based on structural requirements.

The T66 temper treatment really boosts the stability of 6060 aluminum, cutting down on those annoying property variations we see in regular T6 by about 30%. What happens here is that this longer aging process makes the yield strength much more consistent between different production runs, staying within around ±5 MPa range. And guess what? It still manages to keep that 12% elongation intact. Another nice benefit comes from the stabilized microstructure which actually makes the material resist creep better too. At 80 degrees Celsius, it handles thermal stress about 20% better than before. That matters quite a bit when talking about building parts that go through constant heating and cooling cycles. For anyone working on those big curtain wall installations spanning hundreds of feet, choosing T66 treated 6060 extrusions means they won't have to worry about dimensional changes over time, something that becomes super important after twenty or thirty years on site.

The tensile strength numbers tell part of the story. 6063 aluminum does reach around 220 MPa in T6 condition compared to just 210 MPa for 6060. But when it comes to how much the material can stretch before breaking, 6060 wins hands down with 18% elongation versus only 12% from 6063 in similar tempers. This makes all the difference in earthquake-prone areas where building components need to flex under sudden forces without snapping apart. Many structural engineers are now going with 6060-T66 specifically for parts that handle pulling forces, such as those cable systems holding up modern building exteriors. The reason? That extra 15% improvement in strength relative to weight gives it an edge over standard 6063 options in these applications.

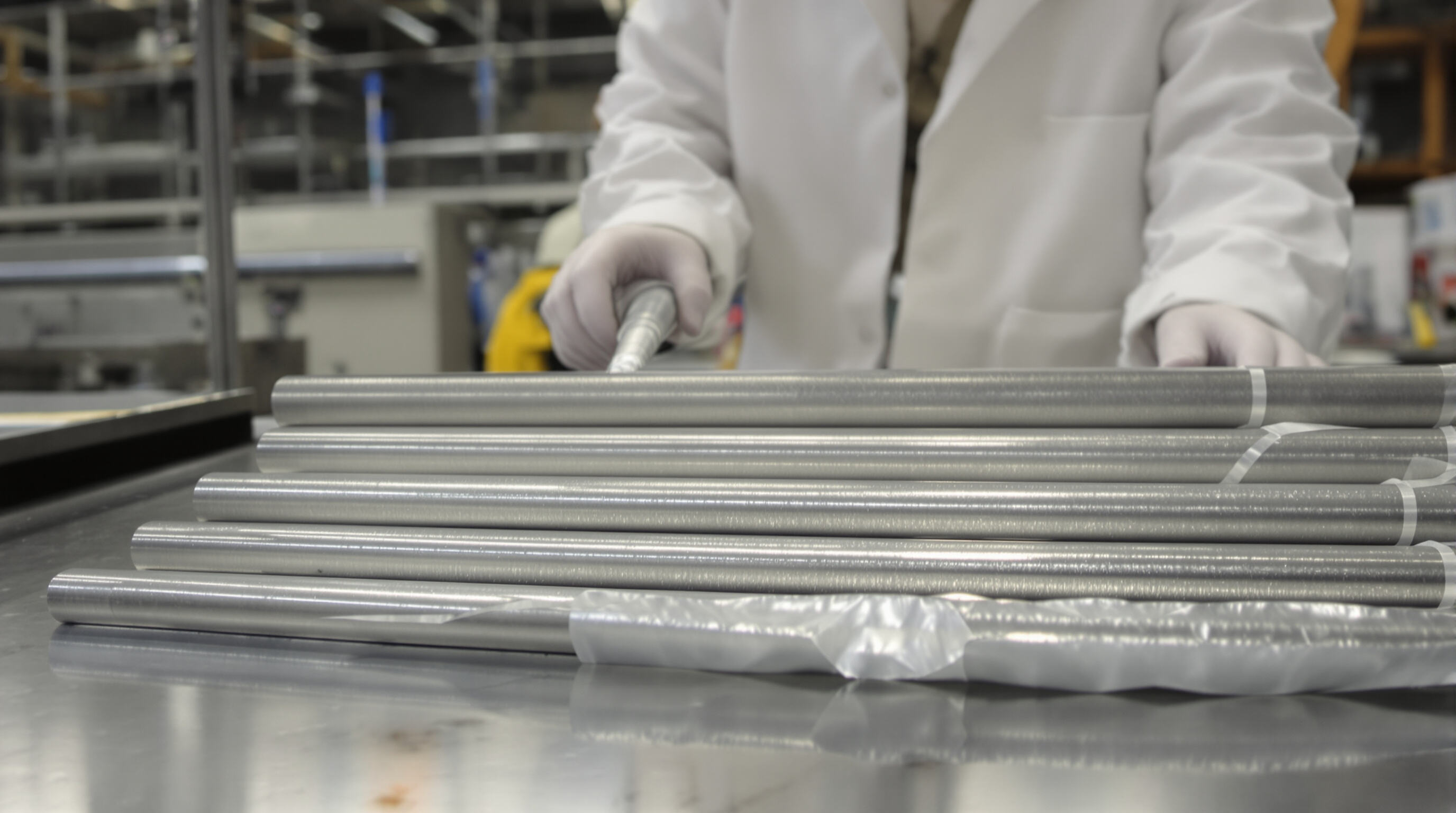

What makes 6060 aluminum extrusion stand out is its special mix of chemicals that really helps it flow well when heated up for extrusion work. The magnesium and silicon content has been fine tuned so the metal stays nice and pliable between around 450 to 500 degrees Celsius. At these temperatures, factory workers can push the material through complex shapes that would break other metals. Because of how smoothly it flows, we can make all sorts of things from complicated multi channel parts to sleek looking trim pieces for cars and buildings. Even better, those fancy architectural profiles with built in thermal breaks come out dimensionally accurate every time they're made.

Tests in real manufacturing settings show that 6060 alloy experiences around 18 to 22 percent less die wear than similar 6005 alloys. This happens mainly because it contains less silicon and handles heat better throughout the process. When working with extrusion presses, this means they can run at speeds between 15 and 18 meters per minute before tools start showing signs of wear out too soon. That makes all the difference when running large batches where downtime costs money. Plus, how stable the material stays during temperature changes cuts down on waste significantly. Many plants report getting their scrap rates below 4% once everything is properly set up and running smoothly.

When working with thin walls between 0.8 and 1.2mm thick, 6060 aluminum extrusions hold their shape about 30% better than regular 6063 alloy after quenching. Manufacturers combine advanced preheating methods for the billets with the material's ability to harden under stress, which makes it possible to produce those tricky hollow sections and intricate micro-grooves needed for heat exchange systems and lightweight structures. The level of control achieved means manufacturers can hit wall thicknesses within plus or minus 0.05mm for components that meet aerospace standards, something that really matters when every fraction of a millimeter counts in critical applications.

The 6060 aluminum extrusion has really good cold forming properties, capable of bending down to about three times the material thickness without any cracks when in T4 condition. What makes this possible is the balanced mix of magnesium and silicon in its composition, which allows architects and designers to create those interesting curved window frames and smooth rounded building exteriors that are becoming so popular these days. Compared to other harder aluminum types, 6060 keeps at least 15% elongation after being formed, something that matters a lot when working on detailed projects where measurements need to be spot on. This characteristic gives fabricators more flexibility while still meeting strict dimensional requirements.

When it comes to creating strong joints in 6060 aluminum extrusions, GTAW and FSW stand out as top performers. These methods manage to preserve around 85 to 92 percent of the original metal's strength, which is pretty impressive for welded connections. For many important industrial uses though, there's an extra step needed after welding. Post-weld heat treatment known as T5 tempering helps bring back the corrosion resistance that gets lost at those weld points. Recent research from structural engineers in 2024 showed something remarkable too. They tested friction stir welded 6060 joints under harsh conditions and found they still held up with a yield strength of 145 MPa even after sitting through 5,000 hours of salt spray exposure. That kind of performance speaks volumes about how durable these welds really are when done properly.

In accelerated exposure tests simulating coastal atmospheres, 6060 aluminum extrusion showed 30% lower pitting depth than standard 6063 alloy after 10 years of equivalent service. Urban pollution resistance benchmarks reveal:

| Environment | Mass Loss (mg/cm²) | Pitting Depth (µm) |

|---|---|---|

| Industrial Zone | 1.2 | 20 |

| Coastal | 2.8 | 45 |

| Rural | 0.7 | 12 |

The alloy's chrome-free pretreatment systems enable 25-year performance warranties in architectural applications, with 94% of European facade projects reporting zero corrosion-related failures since 2018.

6060 aluminum extrusion exhibits superior surface homogeneity due to its optimized silicon-magnesium ratio, achieving <12% reflectance variation across mill-finished surfaces. This consistency enables predictable anodizing results, with 6060 achieving 20–25μm oxide layers at 30% lower energy costs than 6063 alloys.

A 2024 analysis of 42 European curtain wall installations revealed anodized 6060 extrusions maintained 98.6% color stability after 5 years in urban environments, outperforming 6063’s 91.2% rating. The 2024 Architectural Surface Trends Report highlights 6060’s growing adoption in parametric facade systems, where its <0.8μm Ra surface roughness enables seamless light diffusion.

6060 aluminum extrusion reduces embodied carbon by 18% compared to 6063 through optimized extrusion speeds and 22% lower scrap rates. Its Cradle to Cradle Silver certification and 95% recyclability rate align with EU taxonomy requirements, driving specification in 73% of new Net Zero Energy buildings surveyed across Germany and Scandinavia.