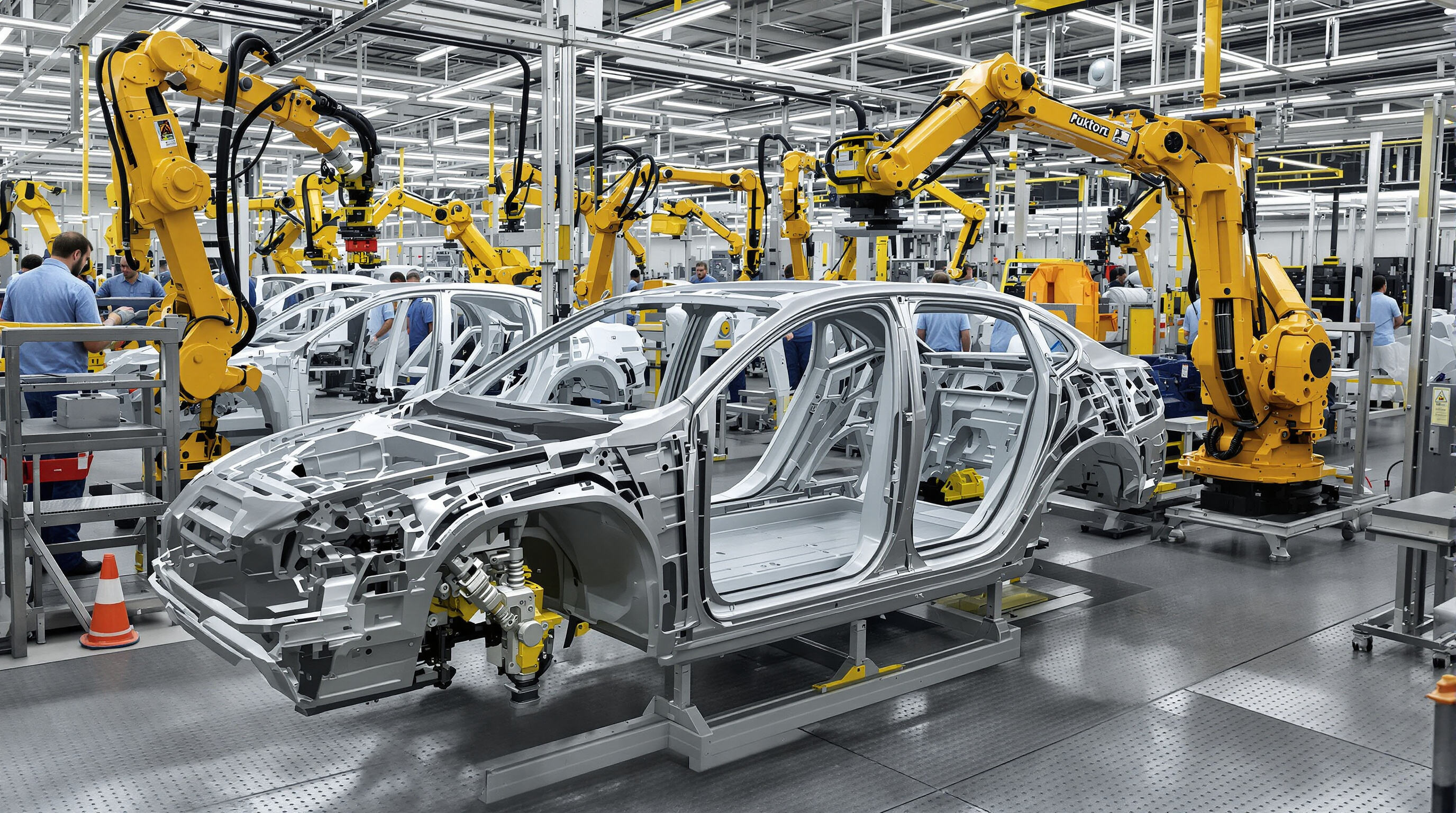

Aluminum alloys from the 6xxx series are now essential for building car frames today because they combine strength with lightness and resist rust really well. According to recent material tests around 2025 timeframe, these alloys can handle about 20 percent more twisting force compared to regular steel, all while making parts roughly 35 to maybe even 40 percent lighter. What makes them so useful is how easy they are to shape during manufacturing. Car makers can form complex structures for crash protection and those special door beams with multiple chambers inside. These designs pass tough safety standards but still keep cars handling nicely on the road.

When it comes to making cars lighter, aluminum extrusion helps automakers cut down on vehicle weight by around 100 to 150 kilograms when compared with traditional steel designs. For gas powered cars, this means about 6 to 8 percent better fuel efficiency at the pump. Electric vehicles benefit even more significantly, getting somewhere between 12 and 15 percent extra driving range from the same battery pack. One area where this really shines is in building battery trays for electric vehicles. The hollow profiles created through extrusion not only make these components lighter but also provide much needed structural reinforcement around those delicate battery cells that are so crucial for EV performance.

Leading EV manufacturers now use single-piece extruded aluminum battery housings that integrate cooling channels and impact buffers into unified structures. These enclosures offer 40% better thermal regulation than traditional welded assemblies and provide crash protection equivalent to 1.8 mm steel at half the weight—key advancements enabling safer, longer-range electric vehicles.

A 2024 automotive engineering report highlights how automakers leverage extruded aluminum profiles to build modular chassis systems. These interlocking components allow rapid platform adaptation across vehicle classes while maintaining consistent crash-test performance, cutting development cycles by 30% compared to conventional stamped-steel architectures.

The aerospace industry relies heavily on aluminum alloy extrusions because they offer such great strength relative to their weight, especially when we're talking about grades like 7075 and 2024. What makes these materials so valuable is that they can reach tensile strengths above 500 MPa but still weigh around 60 percent less than steel, which really matters when trying to make planes fly better. Take wing spar caps as one practical application. When made from extruded aluminum instead of titanium, these components end up being somewhere between 18 and 22 percent lighter, yet they still pass all the FAA requirements for how well they resist fatigue over time. The real world impact? Airlines report saving roughly 2,400 liters of jet fuel each year on every plane that incorporates these lighter parts, something that helps both the bottom line and environmental targets at the same time.

Hot extrusion techniques operating between around 375 to nearly 500 degrees Celsius are what turns those high quality aerospace billets into solid structural shapes without seams. Maintaining just the right heat during processing helps keep the metal's grain structure intact, which means parts such as landing gear actuators will have reliable strength throughout. Factories that switch to these methods typically see their production times drop by about thirty percent compared to old school forging approaches. After extruding, measurements stay really tight too, usually within plus or minus 0.1 millimeters. This kind of precision matters a lot when these parts need to fit together with carbon fiber sections in modern aircraft construction.

The latest extrusion dies allow manufacturers to create complex multifunctional profiles in one go. Take wing ribs for instance these can now incorporate built-in coolant channels along with mounting points for sensors right from the start. According to research published last year, an aerospace company saved around fourteen thousand dollars on each aircraft when they swapped out eighty four separate riveted steel components for a single piece aluminum fuselage made through extrusion. The new design not only cut costs but stood up better to vibrations during flight tests. What's really exciting is how these advanced extrusions meet future aviation needs too. They provide necessary electromagnetic protection around sensitive electronic equipment spaces and feature specially designed shapes that absorb impacts much better than traditional materials do for cargo areas.

Aluminium alloy extrusion has become a cornerstone in modern architectural design, offering engineers and designers unparalleled flexibility in creating structural solutions that balance form and function.

These days, most modern buildings rely heavily on extruded aluminum profiles because they can be manufactured with incredible precision and work well with all sorts of complicated shapes. Take the 6063 alloy for instance it's really popular among builders thanks to how smooth it looks after finishing and how easy it is to weld together. When we put thermal breaks into windows using this material, we actually cut down on heat loss by around 30% when compared to older materials that aren't as efficient. Architects love working with extrusions too since they can create those fancy multi-chambered curtain walls that hold up against pretty serious wind pressures sometimes over 3,500 Pascals without sacrificing that clean, modern look everyone wants these days.

Buildings along coastlines and in big cities are turning to aluminum extrusions coated with PVDF for their exteriors. These coatings have shown amazing durability, standing up to salt air with just 2% corrosion even after quarter century exposure in those salt spray chambers they use for testing (the ASTM B117 standard). Recent research from last year looked at construction materials and discovered something interesting: buildings with aluminum facades needed about three fifths less maintenance compared to steel ones when tracked over 15 years. What makes aluminum so special? Well, it forms this natural oxide layer that actually fixes small scratches on its own, keeping the building looking good even under intense sunlight day after day.

Aluminum extrusion systems do cost about 15 to 20 percent more upfront compared to PVC or wood composite alternatives. But when we look at the big picture, these systems last around 60 years which cuts down on replacement costs by roughly 83% based on various studies looking at product lifecycles. Facility managers have actually seen their maintenance bills drop significantly too, with some reporting as much as 42% savings because there's just not as much painting or sealing required over time. The environmental angle is pretty compelling as well. Most aluminum parts can be recycled again and again without losing quality, with about 95% getting reused versus only about 35% of composite materials. This makes aluminum a smart choice for buildings aiming for LEED certification since it fits nicely into those circular economy models where materials keep circulating rather than ending up in landfills.

Aluminum alloy extrusion has become really important when it comes to managing heat in today's electronics, particularly for making heat sinks. The material conducts heat at around 160 to 200 watts per meter kelvin, which means it moves heat away pretty fast from delicate parts inside gadgets. This helps stop them from slowing down due to overheating. Recent research from 2023 showed something interesting too - devices equipped with these aluminum heat sinks actually had about 32 percent fewer instances where they had to throttle back performance because of heat issues compared to ones made with plastic materials. Considering poor heat management can cut down on how reliable electronics are by as much as 40 percent, many manufacturers now rely heavily on aluminum for things like powerful computer chips and LED lights where keeping temperatures under control matters most.

When it comes to making lightweight yet tough enclosures for things like transformers, solar inverters, and those electric vehicle charging stations we see everywhere now, extruded aluminum profiles really shine. These materials come with built-in protection against electromagnetic interference which keeps those delicate circuit boards safe inside without compromising on strength. What makes them so great is how the extrusion method lets manufacturers build cooling fins right into the design along with proper spots for cables to run through. This means fewer parts to put together during assembly. Some companies report saving anywhere from 18% to almost a quarter off their production costs when switching from traditional welded steel options to these aluminum solutions instead.

The ability of extrusion processes to produce almost any shape has made them popular among manufacturers for creating complex heatsink designs with multiple chambers as well as structures that combine conductivity with insulation properties. When it comes to server rack cooling systems, one piece of extruded aluminum can do the job of between four and six separate stamped components, which cuts down on manufacturing waste by about half according to recent industry findings from last year's materials efficiency study. What really stands out though is how adaptable this method remains when paired with aluminum's complete recyclability factor. For companies looking at long term sustainability goals, these extruded parts offer real advantages over traditional copper based options across both 5G network development and various industrial applications where heat management matters most.

The extrusion process for aluminium alloys creates intricate profiles with tolerances around ±0.1 mm, which cuts down on wasted materials significantly. Traditional fabrication methods just can't match this efficiency. With extrusion, manufacturers get hollow sections and multiple chambers built right into the design. This approach saves roughly 30% in raw materials without compromising strength or durability. What makes it even better is how well it works with recycled aluminum scraps. Most companies find this particularly cost effective since over three quarters of all aluminum extrusions made throughout history are still being used somewhere today because of our ability to recycle them repeatedly in manufacturing cycles.

Aluminum extrusions really work well with circular manufacturing approaches. When we look at what happens after consumers are done with products, the energy required to recycle aluminum scrap is just about 5% of what's needed to produce new aluminum from raw materials. The International Aluminum Institute did some research last year showing that buildings made with extruded aluminum components actually cut down on carbon emissions during operation by roughly 40% when compared to similar structures built with steel over three decades. What makes this even better is our current recycling systems can pull out around 95% of aluminum from old buildings being torn down. That high recovery rate means most architects and builders now see extruded aluminum not just as a good option but often the go-to material for projects aiming to be environmentally friendly.

Steel definitely has more raw strength than aluminum, but when we look at strength relative to weight, aluminum alloys come out ahead by about 60%. That makes all the difference for things like car frames and airplane parts where weight matters so much. Take 6061-T6 aluminum for instance it hits around 310 MPa of yield strength while weighing in at only 2.7 grams per cubic centimeter. Mild steel needs to be pushed to 250 MPa before it even gets close, but at 7.85 grams per cubic centimeter it's nearly three times heavier. The lighter weight saves real money too. Transportation companies report anywhere from 8% to 12% better fuel efficiency when using aluminum instead of steel, as noted in those SAE International studies.

The 6xxx series (6061, 6063, 6082) dominates structural extrusion due to its optimal balance of formability and mechanical properties. Recent market data shows these magnesium-silicon alloys account for:

| Application | 6xxx Series Usage | Key Property Utilized |

|---|---|---|

| Automotive frames | 68% | Crash energy absorption |

| Building facades | 73% | Weathering resistance |

| Electronics cooling | 82% | Thermal conductivity |

This widespread adoption stems from their ability to achieve 150–340 MPa tensile strength after artificial aging while maintaining excellent corrosion resistance.