T slot aluminum frames made through extrusion processes have really taken off in manufacturing circles lately because companies need flexible systems that can keep up with changing production needs. The metal offers something special too: while it only weighs about a third of what steel does, it still manages to hold around 60% of the same strength. That makes it perfect for things like robotic arms, conveyor belts, and those automated workstations we see everywhere now. According to some numbers from the International Aluminum Association back in 2023, there was almost a 20% jump in how many businesses adopted T slot systems last year alone. Why? Because these frames let workers put together equipment without tools and easily rearrange them when needed. Factories are finding they can build entire production lines much faster using these systems than with traditional welded steel setups, cutting down downtime by roughly 30%. Take the auto industry as an example. Car makers use T slot frames to create adjustable jigs on their assembly lines, so they can switch between different vehicle models without tearing everything apart and starting over each time.

More and more industrial automation setups are turning to extruded aluminum T-slot profiles because they offer both precision work and the flexibility needed for changing production demands. Around two thirds of new automation installations throughout Europe and parts of Asia now feature these T-slot frames for things like protecting machinery, mounting sensors, and supporting robotic arms. What makes them stand out is how resistant they are to corrosion, which matters a lot in places where cleanliness is critical such as meatpacking plants or pharmaceutical manufacturing areas. As companies start building their automation systems around modular platforms, the fact that T-slots can be upgraded step by step becomes really important when bringing in those smart connected devices everyone keeps talking about. Take one major car factory for instance, they managed to cut down on retooling expenses quite significantly after making T-slot components standard across all their international locations.

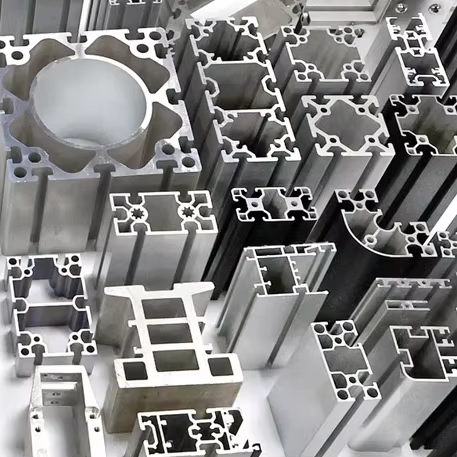

Three factors underpin T-slot aluminum's dominance:

These attributes make T-slot aluminum essential for industries prioritizing agility, durability, and environmental responsibility.

Note: External links were omitted as reference materials lacked authoritative sources meeting linking criteria.

Aluminum T-slot systems made through extrusion have great strength but weigh about two thirds less than their steel counterparts. Engineers love working with these systems when building machine frames or automated equipment since they can handle all sorts of movement stresses without needing massive concrete bases. What makes aluminum so special is how it bends just a little when pressure builds up then snaps back into shape again. This means parts last longer before breaking down compared to those stiff welded metal frames that crack after repeated stress cycles.

Industrial users report 40–50% faster assembly times compared to welded steel, thanks to tool-free bolting and modular design. Facilities eliminate welding labor while gaining the ability to reconfigure lines in hours instead of days. One manufacturer achieved a 27% reduction in material waste through precision-cut T-slot components versus custom-fabricated metal parts.

Aluminum extrusions that have been anodized show about ten times better protection against rust compared to regular steel when tested using the ASTM B117 Salt Spray method. Because of this property, T-slot systems work really well in places like food processing plants, out at sea installations, and laboratory environments where metal oxidation can actually pose serious safety risks. The financial benefits are pretty substantial too maintenance expenses tend to go down around 34% each year. That means no more constant repainting jobs or having to apply galvanizing treatments that are typically needed for standard carbon steel structures. Over time, these savings add up significantly for facility managers looking to cut operational expenditures while maintaining structural integrity.

The ability to rapidly adapt industrial equipment to changing workflows explains why extruded aluminum T-slot systems dominate agile manufacturing. Unlike welded frameworks requiring destructive disassembly, T-slot’s modularity supports infinite layouts with minimal downtime.

T slot profiles come with standard grooves that let workers attach brackets, panels and sensors anywhere they need without having to drill holes first. Most manufacturers face serious delays when changing layouts on welded steel structures. According to a recent study from Industrial Engineering Journal, about three quarters of companies say these changes typically take between three and eight weeks because everything needs to be cut and fabricated again. Aluminum's extrusion properties make all the difference though. Factories can keep stock of universal profiles and completely rearrange workstations or conveyor systems within just a few hours simply by sliding parts along those slots. This flexibility saves both time and money in production environments where adaptability matters most.

Most operators put together around 80 percent of T-slot frames with just basic tools like hex keys and wrenches. No need for any fancy welding gear or expensive CNC machines here. According to industry data, installing packaging lines with T-slot systems takes about 62% less time compared to traditional welded setups. That's a big deal when deadlines are tight. What makes these systems so handy is how easy they are to modify while work is still ongoing. Need to move a safety guard? Just loosen those two bolts and slide it into place. Want to make the base bigger? Grab some pre-cut extrusions from inventory and snap them right on. The simplicity of adjustments saves both time and frustration on the factory floor.

One major car maker cut down on factory stoppages by almost half when they started using T-slot aluminum at their electric vehicle battery assembly lines. The shop floor staff can tweak fixture heights within just ten minutes to fit various battery dimensions these days, whereas previously it took them two whole days to modify those welded jigs. Material expenses dropped significantly too, saving around $360,000 each year because roughly 92 percent of components get reused whenever there's a model changeover. This kind of flexibility makes a big difference in day-to-day operations where time is money.

T-slot systems made from extruded aluminum work so well because they have those precise grooves that fit regular T-nuts, brackets and all sorts of fastening hardware. What makes these systems really stand out is how quickly things can be attached to them. No need for any drilling when mounting panels, installing sensors or adding mechanical parts. That's pretty important stuff for factories running automation lines where downtime costs money. According to the latest numbers from the 2024 Industrial Framing Report, about 8 out of 10 machine builders are going with T-slot aluminum whenever their equipment needs modular additions. Makes sense when considering both time savings and long-term maintenance costs.

Major manufacturers adhere to DIN 65058/ISO 9001 specifications, ensuring ±0.1mm dimensional consistency across suppliers. This cross-brand compatibility allows companies to source globally while maintaining interchangeability—critical for lean inventory strategies. North American plants using standardized systems reduced equipment lead times by 18% compared to proprietary framing (PwC 2023 analysis).

The modular nature of T-slot aluminum supports incremental expansion:

A 2023 Rockwell Automation study found manufacturers using T-slot components required 40% less downtime for production line redesigns than those relying on welded steel structures.

Extruded aluminum T-slot leverages aluminum’s infinite recyclability, with reprocessing consuming 95% less energy than primary production. This closed-loop capability diverts 89% of material from landfills compared to welded steel, supporting circular economy principles without sacrificing performance across reuse cycles.

Tool-free assembly reduces installation time by 40% versus traditional welded frames. Standardized connectors and pre-machined profiles enable rapid setup, cutting labor costs by $18 per linear foot based on 2023 manufacturing efficiency benchmarks.

While steel framing has 22% lower initial costs, extruded aluminum T-slot delivers 31% lower total ownership costs over 15 years. Corrosion resistance eliminates ongoing coating maintenance, and modular reuse—combined with 92% end-of-life material recovery—provides sustained ROI unmatched by permanent welded structures.