Aluminum extrusion takes raw alloy billets and shapes them into precise channel profiles by heating them between 800 to 900 degrees Fahrenheit before pressing them through specially made steel dies using hydraulic force. The process can achieve tolerances as tight as plus or minus 0.004 inches, which is really important when making parts for things like aircraft components or robotic arms where dimensions need to be spot on. After extruding, there are additional steps involving cooling and aging treatments known as T5 and T6 tempers. These processes improve the metal's mechanical properties so that even complicated cross sections maintain consistent strength throughout the material.

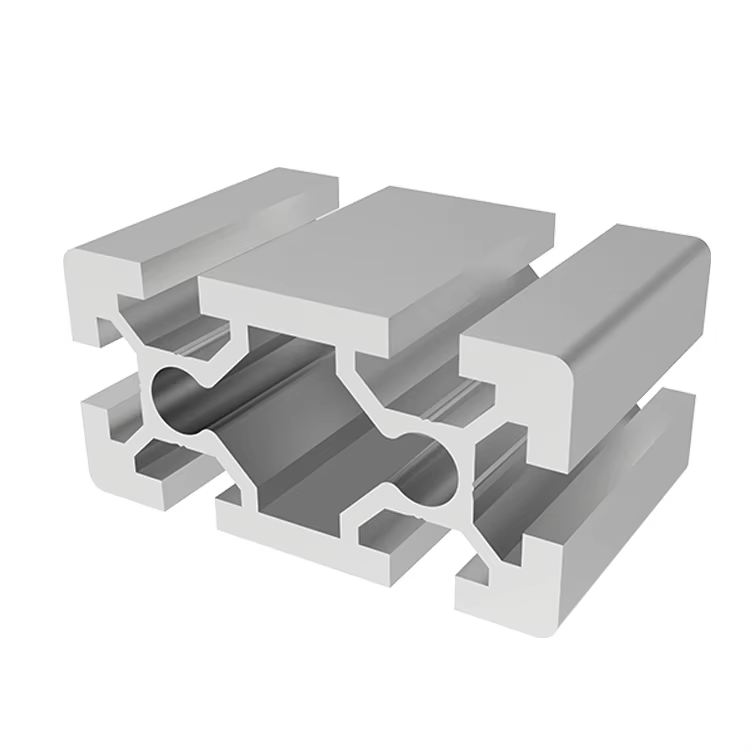

Four primary extruded aluminum channel geometries serve distinct engineering roles:

Each profile is optimized during die design to maintain structural integrity while supporting application-specific functions such as mounting, load transfer, or environmental sealing.

T-slot aluminum channels revolutionize prototyping and industrial design through three core advantages:

This flexibility makes T-slots ideal for agile manufacturing environments where adaptability directly impacts operational efficiency.

Optimal channel selection depends on functional demands:

Key consideration: 6063 alloy offers superior corrosion resistance and surface finish for outdoor architectural use, while 6061 provides higher strength-to-weight ratios for dynamic or load-bearing applications.

The choice between 6061 and 6063 hinges on performance priorities. 6061 delivers higher tensile strength (up to 35,000 PSI), making it suitable for structural frameworks in transportation and machinery. 6063, though slightly weaker, allows tighter dimensional control and smoother finishes—ideal for visible architectural elements like window frames and curtain walls.

Extruded aluminum channel offers a strength-to-weight ratio approximately three times greater than mild steel. This enables lighter designs without sacrificing durability, a critical factor in aerospace systems and automated equipment where reduced mass improves energy efficiency, acceleration, and handling.

Aluminum’s natural oxide layer provides inherent protection against rust and degradation. Industry data indicates less than 0.002% annual material loss in coastal environments (Aluminum Association, 2023). When anodized, these profiles can last over 30 years in marine and chemical processing applications, outperforming galvanized steel in both longevity and maintenance costs.

Field studies confirm extruded aluminum channels withstand over 100,000 fatigue cycles in robotic arm assemblies without failure. Photovoltaic racking systems using these materials have operated for 15 years in high-humidity regions with zero corrosion-related issues—demonstrating a 40% longer service life than comparable steel solutions.

Aluminum T-channel profiles made through extrusion have become pretty much standard equipment in modern robotics and automated manufacturing setups these days. The reason? They just make things easier when putting together machine frames, conveyor systems, and those mounting points for robotic arms. A recent look at industry data from 2023 shows that around 7 out of 10 industrial robots actually run on frames built with aluminum channels. What makes these profiles so useful is their T-slot design. These slots let engineers attach all sorts of components like sensors, actuators, and whatever tools the robot needs to do its job. Plus, maintenance folks can get in there for repairs or upgrades without tearing everything apart first. That kind of accessibility saves time and money in the long run.

Transportation industries have increasingly turned to extruded aluminum channels as a way to cut down on vehicle weight while still keeping things safe enough for road conditions. Take electric cars for instance these days they often incorporate specially designed U-shaped channels around their battery packs not just for protection but also because they help manage heat better during operation. Looking at the skies too we see similar trends where airlines are using those slim C-profile sections in airplane cabins instead of traditional steel parts. Some studies from last year showed this switch could save around 40 percent in weight compared to what was used before. And when planes get lighter obviously they burn less fuel and can carry more cargo at the same time making operations both greener and more profitable for carriers.

More architects are turning to extruded aluminum channels these days when designing curtain walls and structures that need to resist earthquakes. These interlocking profiles shaped like little hats create rain screen facades that can handle pretty serious wind forces, around 150 mph actually, while still allowing for expansion and contraction as temperatures change. Take the recent retrofit work on the Burj Al Arab Tower for example. The project team switched to aluminum channels instead of traditional steel supports and managed to cut down the overall weight of the cladding system by about 30%. This made the whole installation process much easier and put less strain on the building's structure, which is always a good thing from an engineering standpoint.

Engineers enhance performance through strategic integration techniques:

These approaches enable aluminum systems to support dynamic loads up to 12,000 lbs/ft in bridge expansion joints and heavy-duty industrial platforms.

Aluminum extrusions bring several advantages to the table. First off, they're much lighter than steel options – sometimes as much as 60% lighter. That makes them great for applications where weight matters. Plus, these channels naturally resist corrosion without needing special coatings. And let's not forget how easy they are to put together. Most standardized profiles can be assembled quickly with simple bolts and nuts instead of requiring expensive welding equipment. The manufacturing sector has seen real gains from this approach. A recent study looking at automation processes found that when companies switched to modular aluminum assemblies for their robotic systems, installation times dropped around 40%. Makes sense why so many industries are making the switch nowadays.

The extrusion process produces near-net-shape profiles, significantly reducing secondary machining. This cuts post-processing effort by 50–70%, accelerating production timelines—especially valuable in high-volume industries like automotive manufacturing, where workflow efficiencies save 3–5 weeks annually.

Aluminum channels do come with a price tag that's around 15 to 20 percent higher upfront when compared to carbon steel options. But looking at things over time, aluminum actually makes more financial sense. These materials require almost no maintenance work and tend to last well beyond three decades outdoors without showing signs of wear. The numbers back this up too. A recent study from 2024 showed that using aluminum framing instead of galvanized steel can cut down on overall expenses by nearly a quarter over a decade period. For businesses thinking about long term investments, this kind of return definitely matters.

What makes aluminum so sustainable? Well, it can be recycled again and again. When we reprocess aluminum instead of making new stuff from scratch, it takes just about 5% of the energy required for creating virgin aluminum. Pretty impressive, right? And here's another cool fact: more than three quarters of all aluminum ever made is still being used somewhere today because of this closed loop system. Major companies are getting on board too, offering extrusion products made with anywhere between 70% to full 100% recycled materials. The environmental benefits are real too - these efforts cut down carbon dioxide emissions significantly, roughly 8.7 tons saved for every single ton of aluminum that gets recycled instead of discarded.