For engineers, designers, and manufacturing leaders seeking durable, adaptable building solutions, 4040 aluminum extrusion (40mm × 40mm) has emerged as the gold standard in modular framing. Its unique blend of strength, lightweight design, and limitless configurability makes it indispensable across robotics, automation, industrial racks, and advanced 3D printing systems. Here’s why this profile dominates modern engineering—and how to leverage it.

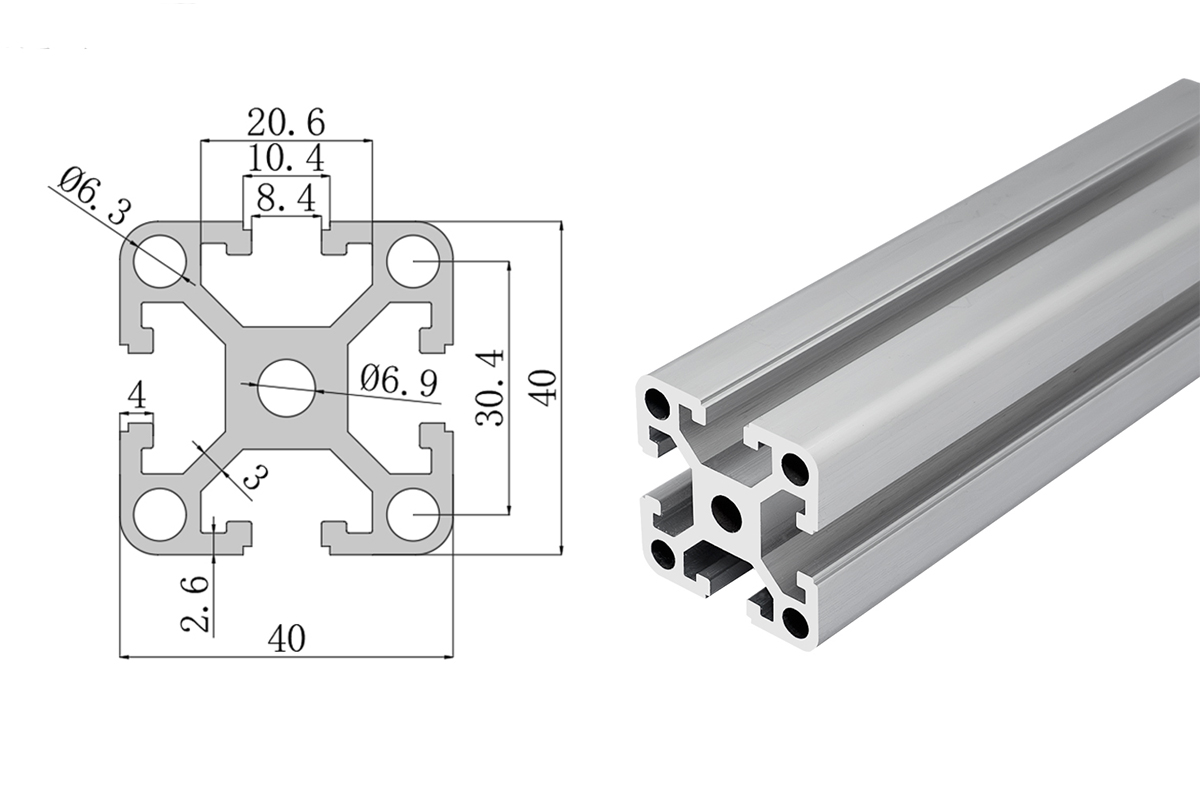

The 4040 profile’s square cross-section integrates T-slots on all four sides, enabling tool-free assembly and component attachment. Unlike welded frames, this allows rapid reconfiguration—critical for agile manufacturing.

Dimensions: 40 mm × 40 mm (standard) | Custom lengths up to 6 m

Material: High-strength alloys like 6061-T6 (σb ≥310 MPa) or corrosion-resistant 6063-T5

Load capacity: Up to 200 kg* (varies by wall thickness: 1.5 mm for light frames → 4.0 mm for heavy racks)

Surface treatments: Anodized (8–25 μm), powder-coated (40–120 μm), or electrophoretic finishes for chemical/wear resistance

* Critical note: Actual load depends on alloy, support type (e.g., fixed ends boost rigidity), and force distribution. Use the bending formula:

δ = (F × L³)/(48 × E × I)

Where δ = deflection (must be < L/1000), E = Young’s modulus (70,000 N/mm² for Al), I = moment of inertia.

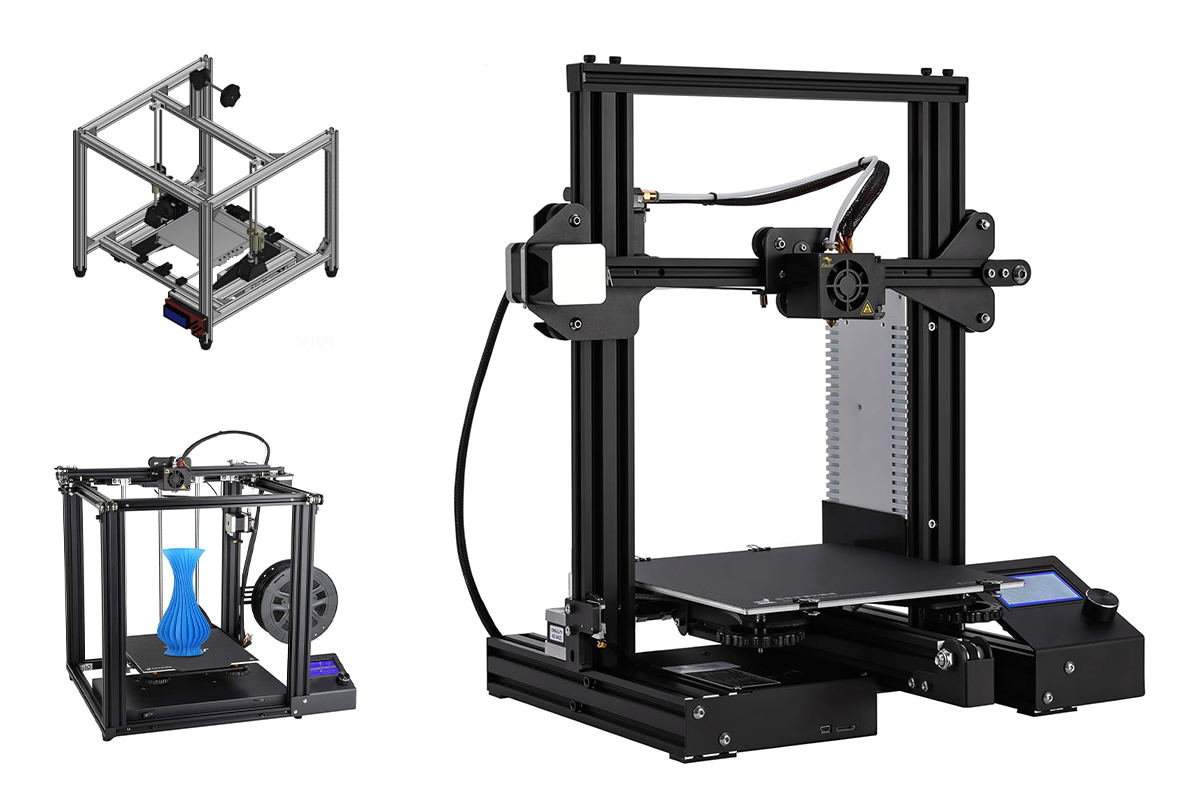

4040’s rigidity withstands vibration in robotic arms. Its T-slots simplify sensor/motor mounting—cutting integration time by 30% vs. welded bases.

Warehouses use 4040 profiles with ≥3.2 mm walls for pallet racks. The alloy’s natural corrosion resistance (enhanced by anodization) prevents degradation in humid environments.

Minimal deflection (<0.5 mm over 500 mm spans) ensures print accuracy. Integrated cooling channels in hollow sections manage motor heat.

Architects specify powder-coated 4040 for solar panel mounts and curtain walls. Its recyclability aligns with circular-economy goals.

| Profile Size | Best For | Load Capacity* | Cost Efficiency |

| 2020 (20×20 mm) | Light fixtures, enclosures | Low | ⭐⭐⭐⭐ |

| 3030 (30×30 mm) | Workbenches, conveyors | Medium | ⭐⭐⭐ |

| 4040 (40×40 mm) | Robotics, racks, printers | High | ⭐⭐ |

| 4080 (40×80 mm) | Bridge cranes, presses | Very High | ⭐ |

| *Compared under identical support conditions |

Key insight: 4040 balances cost and capability. It’s 32% stronger than 3030 but only 18% pricier per meter—ideal for scalable projects.

1.5–2.0 mm: Benches, light frames

2.5–3.0 mm: Conveyors, robotic bases

3.2–4.0 mm: Equipment racks, presses

Use A7075 alloy (ultra-high strength)

Add triangular gussets at joints

Opt for fixed-end supports over pivoting mounts

Leading extruders now integrate IoT and simulation:

Altair HyperXtrude simulates metal flow to predict die stress, cutting trial runs by 90%

ABB’s Low-Force System enables micron-level flatness control for ultra-thin battery foils

SolidThinking Click2Extrude validates load models pre-production—slashing R&D costs

These tools enable custom 4040 variants: hollow chambers for cables, EMI-shielded alloys, or snap-fit connectors.

Not all 4040 is equal. Top suppliers offer:

Alloy flexibility: Switch between 6061 (strength) and 6063 (corrosion resistance)

Tolerance control: ±0.5 mm length cuts | ±10% dimensional accuracy

Value-adds: CNC machining, anodizing, and kit assembly (brackets, fasteners)