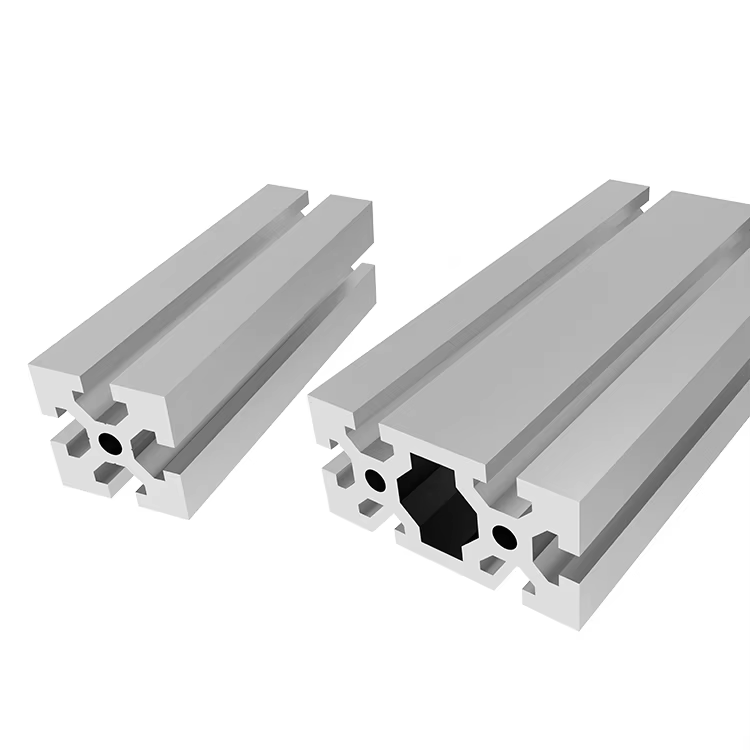

T slot profiles get their usefulness from those carefully made grooves and the specific shape of the aluminum extrusion. Made from 6061 aluminum alloy, they have those distinctive T-shaped channels running the whole length, which makes it possible to mount components without needing tools. With their open edges, T nuts or bolts can just slide right in where needed. And when those fasteners are turned 90 degrees, the undercut edges actually grip them tight and hold everything in place. Some recent tests show this design gives about 40% better strength for the weight compared to regular welded steel options. That kind of performance makes a big difference in many industrial applications.

Industrial structures built with standard slot sizes and extruded profiles offer almost limitless possibilities for rearrangement. Take T-slot systems for instance they work differently from traditional welded frames because workers don't need to take everything apart when making changes. They can adjust widths, heights, move components around wherever needed. Factory personnel literally just slide parts into place rather than cutting metal or waiting for welds to cool. The time savings are impressive too. Most plant managers report being able to shift sensor positions, relocate control panels, or install new support brackets within minutes. Some facilities have seen their workstation redesign expenses drop by somewhere between 50 and 70 percent, especially where production lines handle multiple product variations at once.

The profile's geometric design optimizes mechanical performance through:

These features enable T-slot frames to withstand bending moments up to 1,200 N·m while maintaining alignment tolerances within ±0.5mm, making them suitable for precision automation equipment.

T slot aluminum profiles are pretty much essential in today's industrial automation setups. The grooves in these profiles let workers assemble things like machine guards, frames for robots, and supports for conveyors without needing tools. When compared to welding, T slot systems don't create heat distortion problems and keep alignment within about half a millimeter per meter. This matters a lot when installing delicate parts such as linear guides or camera systems for quality checks. Looking at what manufacturers report, switching to modular framing cuts down on assembly time somewhere between a third and almost half compared to old school welding methods. This means factories can get their production lines up and running much faster than before.

T slot profiles have become a go-to solution for manufacturers wanting to build workstations that fit particular job requirements. These profiles make it much easier to attach things like tool holders, those adjustable monitor arms everyone needs these days, plus ESD surfaces positioned exactly where they should be. According to a recent study from the Material Handling Institute back in 2023, companies that switched to modular aluminum framing saw their workstation redesign expenses drop around 62%. The main reason? They could just reuse components from one project to another instead of starting from scratch every time.

A North American automotive supplier recently deployed T-slot profiles to create reconfigurable robotic welding cells. The system allowed engineers to:

This approach decreased cell reconfiguration costs by $210,000 annually compared to fixed steel platforms.

Advanced manufacturers now combine T-slot framing with IoT-enabled connectors and AI-driven layout simulations. Recent innovations include:

These developments support Industry 4.0 initiatives requiring real-time equipment modifications without production stoppages.

T-nuts and bolts are pretty much essential when working with T-slot profiles since they let us position things exactly where needed without weakening the structure. Those T-shaped channels fit regular M6 or M8 T-nuts that move smoothly along the extrusion until secured with hex bolts. What makes this system so useful is that parts can actually be moved around in fractions of a millimeter while still holding strong with between 2,500 and 3,500 Newtons of clamping force at each connection point. That kind of grip matters a lot for machines that deal with vibrations all day long. Most experienced installers will tell anyone who asks that tightening those bolts to about 80% of what they can handle (usually somewhere between 8 and 10 Newton meters) helps keep the aluminum threads from getting damaged over time.

The internal connectors create those hidden joints inside the profile cavity, making them really good choices when working on clean room equipment or anything where smooth outside surfaces are important. For temporary setups though, external brackets make things go much quicker during installation, about two to three times faster actually, and they can hold around 450 kg each. Some recent testing in real-world situations has indicated that using internal systems cuts down on assembly mistakes by roughly 37% when dealing with complicated framework builds. And speaking of external options, these allow for almost complete tool-free adjustments after everything is put together, something like 92% according to what was measured. Makes sense why many professionals prefer one over the other depending on their specific needs.

The latest spring-loaded cam connectors along with lever lock mechanisms can connect modules in under thirty seconds flat on production lines. What's really impressive is they hold about 85 percent of what traditional bolts can manage but without all those loose parts lying around everywhere. This makes a huge difference in automotive prototype shops where engineers need to tear things apart and put them back together again multiple times each day. Factory floor managers across the industry have noticed something too – switching to these standardized quick connect systems cuts down labor hours by nearly two-thirds compared with old-fashioned fastening methods. Some plants saw their setup times drop dramatically after making the switch last year.

Friction joints work best when there's consistent pressure applied, making them great for situations where loads don't change much. These joints can hold within a range of 0.05 to 0.12 millimeters even when facing stresses below 500 Newtons per square meter. On the other hand, reaction force designs do something different by actually redirecting forces through their shape and how they fit together. This approach gives about 3.8 times better impact resistance, which is really important for things like robotic arms that need to change direction suddenly during picking and placing operations. Looking at real-world installations, most automation experts (around 89%) tend to go with hybrid solutions that mix both approaches when dealing with parts of the system where loads matter most. Makes sense too since no single method works perfectly in all scenarios.

Studies show that T-slot profile systems can cut down on assembly time anywhere from about 30% to nearly half when compared with traditional welded frameworks. What makes these systems so efficient is their bolt together approach which gets rid of the need for welding, grinding work, and hiring special labor forces. Plus, everything comes apart completely for later reuse. Manufacturers love this flexibility because it cuts down on wasted materials. Looking at recent surveys, around two-thirds of companies have reused their T-slot parts in three different projects or more, whereas only about one in eight managed similar results with welded frames.

The cold-assembly process prevents warping caused by welding arc temperatures (often exceeding 1,500°C). Extruded profiles maintain ±0.2 mm/m straightness tolerance, ensuring precise component positioning for robotics and metrology applications. Unlike welded joints requiring post-fabrication machining, T-slot channels serve as built-in alignment guides.

Adaptive manufacturing layouts benefit from T-slot profiles' tool-free adjustability. Facilities report 90% faster line reconfiguration when using modular framing versus permanent welded structures. The system's flexibility supports evolving automation needs—mounting points can be relocated in under five minutes without compromising structural integrity.

When looking at how rigid a T-slot profile is, it turns out geometry matters more than just what material was used. The area moment of inertia, or I-value as engineers call it, basically tells us how well something resists bending forces. Then there's the torsional constant J which measures how much twisting happens when torque gets applied. Take two standard 45x45mm profiles for instance they might look identical from the outside but their actual stiffness could vary by around 30% depending on what's going on inside those walls. According to recent design guides from manufacturers working with aluminum T-slots since 2024, adding ribs to the interior walls makes a real difference. These reinforced sections boost those important I-values by nearly half compared to regular hollow profiles without any internal support structures.

6060-T6 and 6105 aluminum alloys dominate industrial T-slot systems, offering tensile strengths between 160–240 MPa. While 6105 provides 12% greater yield strength than 6060, it increases weight by 8% per linear meter. Applications requiring frequent reconfiguration often prioritize 6063-T5 alloys, which balance machinability (85 HB hardness) and density (2.7 g/cm³).

Use Euler-Bernoulli beam equations for static load calculations:

Deflection = (5 * Load * Length³) / (384 * E * I)

Where E = 69 GPa (aluminum's modulus). For dynamic robotic arms producing 150N cyclic loads, deflection should not exceed 1/500th of span length to maintain positional accuracy.

Industrial automation frameworks require minimum safety factors of 3:1 for vertical loads and 4:1 for cantilevered sections. Critical medical equipment using T-slots often implements 5:1 margins, reducing permissible stress to 80 MPa for 6061-T6 extrusions.

Thin-wall extrusion techniques now achieve 22% weight reduction while maintaining equivalent load capacities through optimized I-beam cross-sections. Powder-coated 6005-T5 extrusions demonstrate a 17% better strength-to-weight ratio than standard alloys, making them ideal for collaborative robot mounting systems requiring <3kg/m linear density.