The cross-sectional shape of aluminium frame profiles directly influences their structural efficiency and application suitability. Geometric design determines load-bearing capacity, torsional resistance, and compatibility with joining systems. Engineers prioritize profile geometry to achieve optimal strength-to-weight ratios while minimizing material waste.

When it comes to structural framing, square and rectangular aluminum tubes are pretty much everywhere because they handle bending forces so well. The numbers back this up too these shapes can take on 40 to 60 percent more weight when compared to round tubes used in similar truss systems. That said, round tubes still have their place especially where things need to rotate smoothly like conveyor belts or those fancy curved building exteriors we see nowadays. Looking at recent data from an architectural materials report published last year, rectangular profiles make up nearly 60% of all structural framing in contemporary warehouse designs. Makes sense really since most storage facilities need strong, stable structures that won't buckle under heavy loads.

C-shaped channels offer open access for wiring and piping integration in modular partitions. U-shaped profiles create natural seating for glass panels in curtain walls without additional brackets. These configurations reduce assembly time by 25—35% compared to complex fabricated supports according to industrial design benchmarks.

H-profiles mimic steel I-beams’ load distribution capabilities while weighing 50% less, making them ideal for overhead gantry systems. T-shaped variants serve as structural spines in shelving units and solar array mounts, with flanges preventing lateral displacement under dynamic loads.

The 90° bend in L-profiles makes them effective corner brackets for window frames and machinery enclosures. This shape simplifies modular construction by providing pre-engineered joining points for perpendicular components, reducing welding requirements by up to 70% in prefabricated structures.

Aluminium frame profiles serve distinct functional roles across industries, with building and manufacturing sectors utilizing specialized designs for targeted performance. Below are key classifications:

Engineers use extruded aluminium profiles with rectangular or square cross-sections for structural frameworks in bridges and industrial facilities. These typically employ 6061-T6 alloy, achieving tensile strengths over 45,000 psi while offering 40% weight savings versus steel.

Insulated aluminium profiles incorporate polyamide thermal barriers that reduce heat transfer by 60% compared to solid extrusions. This design prevents condensation and meets ENERGY STAR® requirements, making it essential for modern curtain walls and low-emissivity glazing systems.

Thin-walled channel profiles secure glass panels in high-rise façades through compressive force distribution, with integrated gasket grooves ensuring airtight seals. Bead profiles allow tool-free installation of architectural louvers and signage via snap-fit mechanisms.

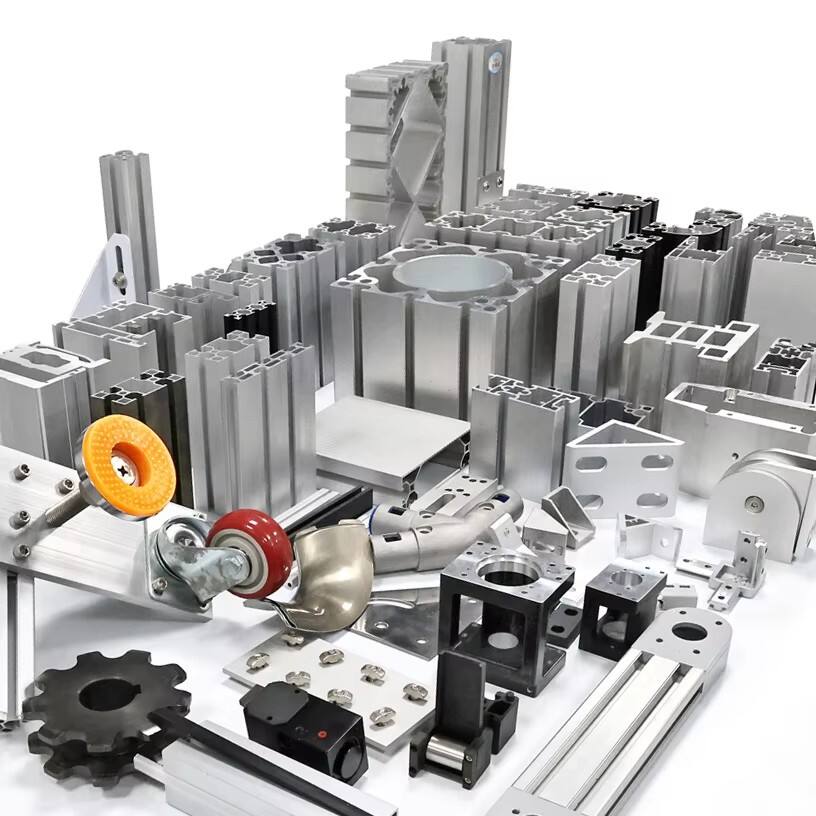

T-slot aluminium framing systems dominate industrial automation infrastructure due to their modular reconfigurability. The standardized slotting pattern enables 87% faster assembly of production lines compared to welded steel frames, with vibration damping properties extending equipment lifespan.

Common aluminium frame profiles such as L-shaped angles, T-sections, and U-channels offer affordable ready-made options for everyday structural requirements. Most of these factory made shapes comply with ISO 9001 quality standards which makes putting them together fast for things like storage racks or simple machine bases. The consistent sizing really helps when designing structures, especially since rectangular tubes measuring around 40 by 80 millimeters and those angled pieces with dimensions roughly 25 by 25 by 3 mm thick are so commonly found in modular building projects across various industries.

For projects needing unusual shapes like internal cooling channels in HVAC systems or built-in cable pathways, custom aluminum profiles really shine when it comes to getting the most out of materials. According to last year's Design Trends Report, around two thirds of all industrial automation work these days is using made to measure profiles, cutting down on parts needed by roughly thirty to forty percent. What makes this approach so valuable is that engineers can actually combine several different functions mounting slots, space for thermal expansion everything into one piece instead of having separate components. This cuts down on both the time spent putting things together and the overall weight of the finished product.

For a solar farm built in one of those dry desert regions where sand storms are common, engineers needed aluminum profiles that could handle both twisting forces and constant sand wear. They went with custom made 150 by 150 millimeter box profiles fabricated from 6063-T6 alloy. These profiles had special internal baffles inside to keep dust from getting everywhere, plus they came already drilled with slots so installers could adjust the tilt angles as needed. The result? On site work took about half the time it normally would with those old fashioned bracket systems. And these profiles stood up just fine against winds blowing over 140 kilometers per hour, which is pretty impressive considering how harsh desert conditions can be for equipment.

Most standard profiles arrive within about 2 to 3 business days and cost somewhere between $8 and $15 per linear meter. Custom made solutions take much longer though, usually around 6 to 8 weeks because they need special tooling and manufacturing setup. Industry experts have looked into this stuff quite a bit, and their findings show that going custom can actually save companies anywhere from 18% to 27% over time when used in large quantities. These savings come mainly from needing less maintenance work and cheaper assembly processes down the road. When dealing with prototypes or smaller orders, many manufacturers find that mixing things up works best. Taking a standard profile and adding some extra machining touches often hits that sweet spot where initial costs stay reasonable but still meets all the necessary performance specs.

The 6063 aluminum alloy makes up about 68% of all architectural framing systems around the world because it strikes just the right balance between how easy it is to extrude and its ability to resist corrosion. What makes this alloy special is its magnesium-silicon makeup which gives it those really smooth surfaces perfect for things people actually see, such as window frames or curtain walls on buildings. According to data from Aluminum Association in 2023, this material has a yield strength of approximately 21 MPa. That might not sound super strong compared to other metals, but it works great for parts that don't need to hold heavy loads. Plus, manufacturers love working with it since they can create complex shapes at reasonable costs during the extrusion process.

While 6063 prioritizes formability, 6061 aluminium delivers superior mechanical performance for industrial frames. Possessing 276 MPa tensile strength—40% higher than 6063—this alloy is preferred for machinery bases, robotic arms, and structural trusses. Its copper-enhanced composition withstands repeated stress cycles in automation systems but requires protective coatings in corrosive environments.

| Property | 6063 Alloy | 6061 Alloy | Environmental Consideration |

|---|---|---|---|

| Corrosion Resistance | Excellent (1.8 µm/yr) | Moderate (3.2 µm/yr) | Coastal/chemical exposure favors 6063 |

| Thermal Conductivity | 201 W/m·K | 167 W/m·K | 6063 preferred for heat sinks |

| Weldability | Superior (no cracking) | Requires pre/post-heating | 6063 simplifies on-site assembly |

When it comes to architectural applications, anodizing works really well with 6063 aluminum profiles. This process creates those tough oxide layers around 25 to 30 micrometers thick that stand up pretty good against UV damage over time. Industrial frames made from 6061 aluminum are usually better suited for powder coating though. The coating hits about 9H hardness according to MIL-DTL-53072 standards and lets manufacturers mark different colored safety areas right on the frame itself. Something interesting has happened recently too. New developments in plasma electrolytic oxidation technology are starting to produce these hybrid coatings. They basically take what makes 6063 so resistant to corrosion and mix it with the kind of wear resistance we typically see in 6061 materials. Manufacturers are watching this space closely as potential game changer for their product lines.